Pojęcie

Fundamentals of Smoke Control

One of the most hazardous situations that can be faced in a building is smoke. While fires themselves are often damaging, it is smoke that can cause the most injuries.

In order to protect a building’s occupants, as well as furnishings and equipment that may be damaged by smoke, a smoke control system is needed. A smoke control system controls the flow of smoke in a building in the event of a fire. It keeps smoke from spreading throughout the building and gives the building’s occupants a clear evacuation route, as well as preventing further damage to the building’s interior.

The primary means of controlling smoke movement is by creating air pressure differences between smoke control zones. The basic concept of building pressurization is to establish a higher pressure in adjacent spaces than in the smoke zone. In this way, air moves into the smoke zone from the adjacent areas and smoke is prevented from dispersing throughout the building.

Smoke control systems are either dedicated or non-dedicated. A dedicated smoke control system is installed in a building for the sole purpose of controlling smoke. It is a separate system of air moving and distribution equipment that does not function under normal building operating conditions. Dedicated systems are used for special areas, such as elevator shafts and stair towers that require special smoke control techniques.

Non-dedicated smoke control systems are systems that share components with some other systems such as the building automation (HVAC) system. When activated, the system changes its mode of operation to achieve the smoke control objectives.

The goal of a fire control system is to contain and extinguish the fire as fast as possible. Fire control systems halt the fire, but not the smoke, and are often triggered automatically by the heat of the fire. These systems rely on a water supply, such as sprinklers, whereas smoke control systems usually rely on electricity to run fans and dampers.

The smoke control system is usually separate from the fire control system because they have different goals. However, the smoke control system should be designed to work with the fire control system and not interfere with its operation. For example, if the building has a sprinkler system, then the smoke control system does not need to control a large quantity of smoke because the size of any fire should be smaller.

Moreover, if a smoke control system is working with a gas-based fire extinguisher, certain actions must be taken. If the smoke control system tried to vent a room with a gas-based fire extinguishing system, it would probably vent the smoke along with the fire suppressing gas. Removing the gas lets the fire continue burning. Therefore, gas-based fire extinguishers and smoke control systems should not be active at the same time in the same area.

Smoke control systems receive the location of the fire from the fire panel. The fire panel uses a combination of smoke and heat sensors to determine where the fire is located. In the event that signals are received from more than one smoke zone, the smoke control system should continue automatic operation in the mode determined by the first signal received.

Basic System Types

Building smoke control systems can generally be divided into two basic types: shaft protection and floor protection. Shaft protection consists of stairwell pressurization systems and elevator hoistway systems. Floor protection involves several variations of zoned smoke control. Use of a particular system or combination of systems is dependent on building and fire code requirements as well as specific occupancy and life safety requirements of the situation being considered.

Recent trends have indicated areas of refuge are being designed into many buildings as dictated by the Americans for Disabilities Act (ADA). Specifications may refer to these areas of refuge which are typically located adjacent to stairwells or elevator hoistways. These refuge zones may require special pressure compensation systems to maintain a tenable environment. The requirements for these systems must be dictated by the building's smoke control system designer based on the smoke control system design and its associated sequence of operation. When these types of zones are encountered, additional time and resources may be required to establish and verify compliance to the specification.

There are two types of shaft protection systems:

Stairwell pressurization systems

Elevator smoke control

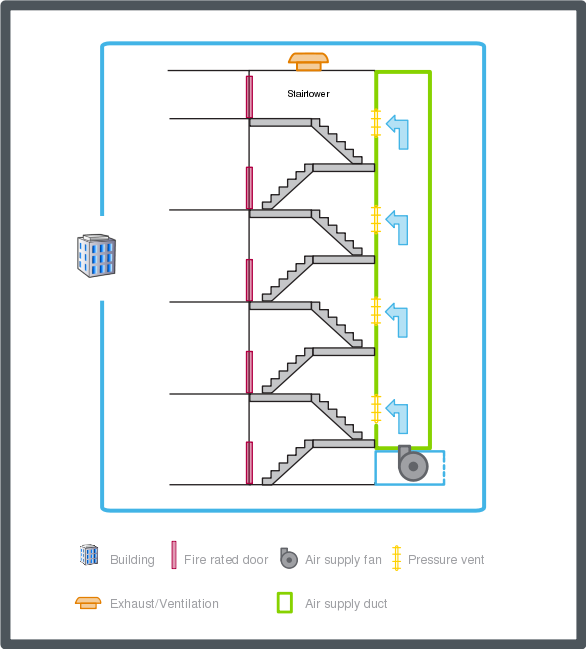

Stair towers are stairwells with a ventilation system and are isolated from the main building. Stair towers are the most common type of dedicated smoke control system. The only connection between the building and the stair tower is the fire-rated doors on each floor. Because the building’s occupants should use the stair tower to leave during an evacuation, keeping the stair tower smoke free is vital. The following image depicts the various parts of a stair tower system.

The goal of pressurized stairwells is to maintain a tenable environment within exit stairwells for the time necessary to allow occupants to exit the building. A tenable environment is defined as an environment in which the products of combustion, including toxic gases, particulates, and heat, are limited or otherwise restricted to maintain the impact on occupants to a level that is not life threatening. A secondary objective of stairwell pressurization is to provide a staging area for firefighters. This is achieved when stair shafts are mechanically pressurized, with respect to the fire area, with outdoor air to keep smoke from contaminating them during a fire.

There are two types of stairwell systems:

Noncompensated– Supply air is provided to the stairwell by starting a fan. This provides two or more positive pressure differentials: one differential with all of the doors closed, a second differential with one door open, and so on.

Compensated– Supply air is also provided to the stairwell by starting a fan, but the fan system adjusts the positive differential based on the various combinations of opened and closed doors. You can perform this adjustment by either modulating supply airflows or by relieving excess pressure from the stairwell. Typically, over-pressure relief may utilize barometric dampers, motor-operated dampers, an automatically opening stairwell door to the outside at ground level, or an exhaust fan.

It is important to pressurize a stair tower enough to keep smoke out. However, if the pressure in the stair tower is too great, opening the door leading into the stair tower can be difficult.

Elevator shafts present a particular problem with regards to smoke control. The elevator shafts form perfect chimneys to draw smoke into the upper levels of a building. Since elevators usually have openings on each floor, and the seals on elevator doors are often poor, the elevator shaft can become a mechanism to spread smoke throughout a building.

In order to have a usable elevator during a smoke emergency, the elevator shafts have to be pressurized in the same way a stair tower is pressurized. However, pressurizing the elevator shaft presents a number of problems. You can fit the elevator doors with improved seals and rubber sweeps. However, these steps do not completely eliminate air leakage. Moreover, most elevator shafts are not designed to be pressurized. There are also localized pressure differences that the cars create as they travel up and down the shafts. Shafts are often constructed of porous material that cannot contain the air pressure. Shafts are not designed for inspection after the elevators are installed, so finding and repairing cracks that would let smoke infiltrate or pressure escape is difficult.

While several methods for correcting the problems of air pressurization in elevators have been proposed and investigated, there are no firm recommendations regarding elevator smoke control. Refer to the NFPA 92 and UL864 standards for additional information. Remember the local AHJ and project specifications may require control beyond that specified in the above standards.

As discussed previously, pressurized stairwells are intended to control smoke to the extent that they inhibit smoke infiltration into the stairwell. However, in a building with just a pressurized stairwell, smoke can flow through cracks in floors and partitions and through other shafts to threaten life or damage property at locations remote from the fire. The concept of zoned smoke control is intended to limit this type of smoke movement from within a building.

With zoned smoke control, smoke movement is inhibited by dividing the building into smoke control zones, with each zone separated from the others by smoke barriers. These smoke barriers can include partitions, floors, or doors that you can close. When a fire occurs in one of these smoke control zones, it is called a smoke zone. In the event of a fire, pressure differences and airflows produced by mechanical fans and operating dampers can be used to limit the smoke to the zone in which the fire originated. When a fire/smoke condition occurs, all of the nonsmoke zones that are contiguous to the smoke zone are positively pressurized and the smoke zone is negatively pressurized. Optionally, all of the remaining smoke control zones in the building may also be positively pressurized. With the smoke contained to the smoke zone, it can then be exhausted. Typically, the fire/smoke signals from a protective signaling system (UOJZ, a UL 864 Listed Fire Alarm Control Unit; that is, a fire alarm panel) are used to activate the zoned smoke control sequence.

Smoke Control System Activation

The operating controls of the HVAC system shall be designed or modified to provide the smoke control mode with the highest priority over all other control modes. Normally, the smoke control sequences are activated automatically. In some cases, however, manual activation may be more appropriate. In either case, the smoke control system shall be capable of being manually overridden and manually deactivated. The automatic smoke control system shall be automatically activated in response to signals received from a specific fire detection device or a combination of fire detection devices. Fire detection devices include automatic devices such as smoke detectors, waterflow switches, and heat detectors. Generally, manual fire alarm pull stations should not be used to activate automatic smoke control systems, other than stairwell pressurization systems. The reason for this is because of the likelihood that a person may signal an alarm from a station outside of the smoke zone origin.

Smoke control system activation should be started immediately after receiving an activation command. A maximum of 10 seconds transmission time is allowed, from the initiation of an activation signal (that is, a fire alarm input), to the time it reaches the smoke control system. The smoke control sequence should activate individual components and starts from the moment the smoke control command is issued (whether automatic or manual) to the final action. This time is 60 seconds for fan operation at the desired state and 75 seconds for the completion of the damper travel. Should an individual component fail, the time lapse from the moment the component reaches its final state and the moment its associated trouble signal annunciates should not exceed 10 seconds. This means that the annunciation of the trouble signal for a fan must occur within 70 seconds of the automatic or manual activation command. The annunciation of the damper trouble signal must occur within 85 seconds of the automatic or manual activation command.

This table summarizes the control and supervision time constraints applied by the UL 864 listing and NFPA 92. The applications within the Automation Server, AS-P and field controllers shall provide compliance with the following.

|

Function |

UL 864 Required Timing (Maximum) |

|

Controller Offline/Trouble Detection |

200 Seconds |

|

Fan Proof Sensor Time Limit |

60 Seconds |

|

Damper Activation Proof Sensor Time Limit |

75 Seconds |

|

Audible Trouble/Fault Signal Resound Of Horn |

24 Hours |

Once an automatic activation has occurred, subsequent alarm signals that would normally result in the automatic actuation of a smoke- control sequence should be annunciated only. No fans or dampers should be actuated in response to any subsequent automatic alarm signal in order to avoid the possibility of defeating any smoke control sequence which is in progress.

EcoStruxure BMS Hardware Overview

EcoStruxure BMS Hardware Overview

Smoke Control Operational Overview

Smoke Control Operational Overview

EcoStruxure BMS Smoke Control for BACnet MS/TP

EcoStruxure BMS Smoke Control for BACnet MS/TP

FSCS Basics

FSCS Basics

Smoke Control System Restrictions

Smoke Control System Restrictions