Concept

Weekly Self-Test

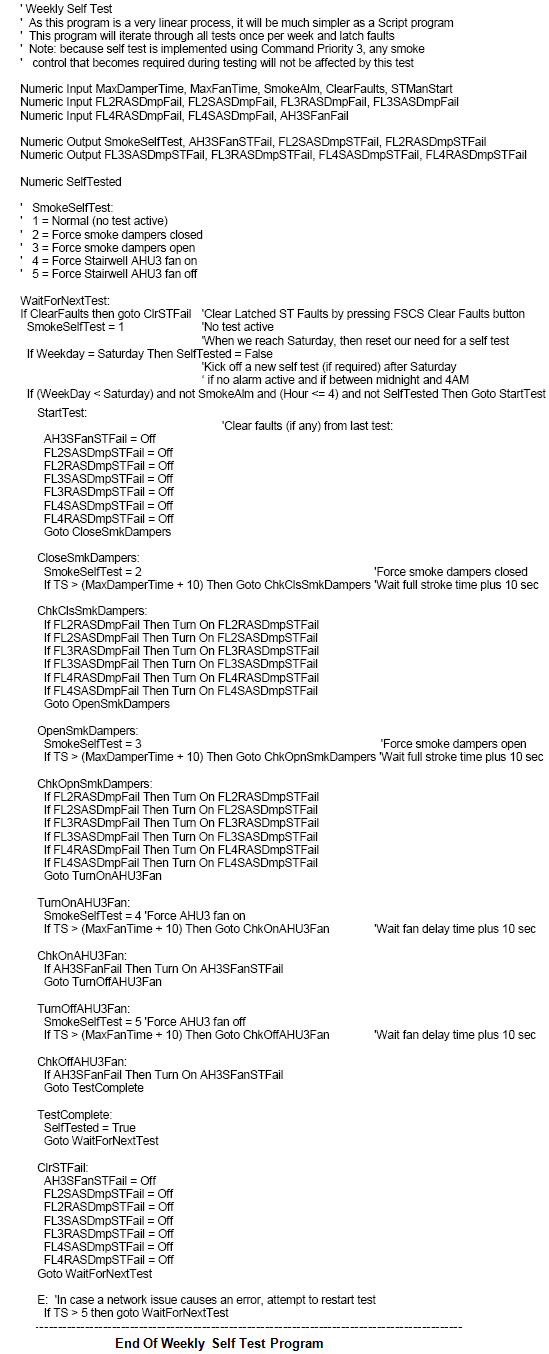

The dedicated smoke control equipment in the system must be activated and tested a minimum of once a week. This type of task is best suited for Script programming. The following shows a weekly self-test program for the example system. The program waits until after midnight on Saturday night and starts the test. Any equipment faults latched during the previous self-test are cleared.

The program maintains a variable SmokeSelfTest to move from normal/idle state (1) and sequence through the 4 active test states (2 to 5). This variable is sent to the controllers managing dedicated equipment. The controllers will initiate the applicable action on the dedicated equipment and the equipment fault status is monitored by the Smoke Control Server running the self-test shown program.

If an equipment fault is detected, the fault condition will be latched in the self-test program for presentation on the FSCS. This allows the operator arriving on Monday morning (or any time after the self-test) to be notified of the equipment self-test failure. The latched faults are cleared with a pushbutton on the FSCS panel.

The program sequences the SmokeSelfTest output to the following values:

2 Test smoke dampers in closed position

3 Test smoke dampers in open position

4 Test stairwell pressurization (AHU3 fan on)

5 Test stairwell normal AHU3 fan off)

After setting the SmokeSelfTest variable directing which test is to be performed, the program will wait for the maximum equipment transition time + 10 seconds. After the delay, the program checks all of the applicable equipment fault signals from the various controllers. If an active fault is detected, it is latched into a variable where it will be maintained until the self-test fault is cleared by the user from the FSCS. If not cleared, the following weekly test will clear the fault signals before running the tests again.

Basic Application Functions

Basic Application Functions

FSCS Communication Status

FSCS Communication Status

General Communications Conventions

General Communications Conventions

Equipment Fault Detection

Equipment Fault Detection