Conceito

SMI Blind Outputs

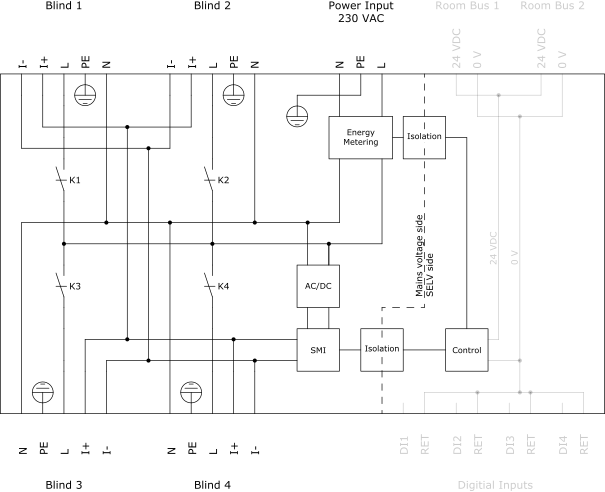

The SMI high-voltage blind modules have four Blind outputs for control of motorized window blinds (drives) that are powered by AC mains voltage (230 VAC). The Standard Motor Interface (SMI), AC version for AC mains-supplied drives, is used to control the blind motors.

The blind module provides one SMI channel. The blind module acts as a controller for the blind motors.

A maximum of 16 blind motors can be controlled by a blind module. The maximum number of blind motors per module and per output is also determined by the module's power distribution limitations. For more information, see section “Specifications”.

The Blind output connector has five terminals for SMI blind motor control and power distribution:

I+ (Control line +)

I- (Control line -)

N (Neutral)

PE (Protective earth ground)

L (Line)

For information on the color coding of the wires for connecting SMI systems, see the SMI Standard Motor Interface website, standard-motor-interface.com

The four power outputs are independently controlled.

The SMI high-voltage blind module uses one relay per output to connect or disconnect the AC mains voltage to the L (Line) terminal and the connected blind motor. In the figure above, the relays are named K1 for the Blind 1 output, K2 for the Blind 2 output, and so on.

The relays are typically always switched On to power the blind motors being controlled, but the relays can be switched Off for different reasons.

The relays can be inadvertently put in the On state due to mechanical shock during transportation. To put the relays in the Off state, ensure that the blind module is powered up by the RP-C room bus (24 VDC) before turning on or connecting the AC mains voltage (230 VAC).

The module's AC mains voltage side and low-voltage side (SELV side) are galvanically separated by means of isolation circuitry.

The module also has energy metering circuitry that supports the measurement of the energy consumption for the total load connected to the module. Para mais informações, consulte RP Controller Expansion Module Energy Metering .

The SMI interface enables accurate positioning of window blinds. Accurate positioning is necessary when several blinds, awnings, or roller shutters are to be aligned. The blind module transmits the desired position through the control wires (I+ and I-) in the form of a digital command, and the electrical motor moves the blind accurately to the desired position using an internal regulator. The SMI blind motors (drives) have the end stops at the top and bottom positions pre-programmed.

The data transmission is bi-directional. The blind module transmits digital commands to the blind motor (drive), and the drive provides feedback to the module in the form of status messages. The feedback from the SMI blind motor drives is necessary when large installations are to be operated efficiently. Conventional blind motors do not support feedback.

The SMI interface supports not only commands for positioning of the blinds, but also commands for querying their current positions, and for diagnosis. The diagnostic commands can be used to detect non-operational blind motors.

For venetian blinds that use one motor drive to control both the position of the blinds and the angle of the slats, the angle of the slats is controlled by sending a command for changing the position of the blind. The mechanics of the venetian blinds is such that the up/down movement of the blinds begins with a rotation of the slats. To achieve absolute control of the angle of the slats, measurements and calibration need to be performed during commissioning. The angle of rotation for the slats, that is, the complete rotation, needs to be measured in degrees. The result from the measurements is entered in the EcoStruxure Building Operation software to calibrate the angle of the slats. Para mais informações, consulte Configuring Blinds in RP Controller Expansion SMI High and Low Voltage Blind Power Modules .

Especificações

Outputs

|

4, Blind 1 to Blind 4

|

Output terminals

|

N, PE, L, I+, and I-

|

Number of SMI channels

|

1

|

Maximum total number of blind motors (drives)

|

16

|

Power distribution

|

230 VAC (same voltage as power supply)

|

Maximum 2 A load per output

|

|

Maximum 8 A total load for the 4 outputs

|

RP Controller Expansion Modules and Multi-sensors

RP Controller Expansion Modules and Multi-sensors

Blind Modules

Blind Modules

RP-C-EXT-BL-SMI-4-HV-PD

RP-C-EXT-BL-SMI-4-HV-PD

RP Controller Expansion Module Pluggable Connectors

RP Controller Expansion Module Pluggable Connectors

RP Controller Expansion Module Energy Metering

RP Controller Expansion Module Energy Metering

Configuring Blinds in RP Controller Expansion SMI High and Low Voltage Blind Power Modules

Configuring Blinds in RP Controller Expansion SMI High and Low Voltage Blind Power Modules

Perigo

Perigo