This section provides grounding and power recommendations for system configurations with Operator Display, which supports 24 VDC input power.

Warning

Warning

|

|

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Remove all power from the device before removing any covers or elements of the system, and prior to installing or removing any accessories, hardware, or cables.

Unplug the power cable from both this product and the power supply prior to installing or removing the product.

Always use a properly rated voltage sensing device to confirm power is off where and when indicated.

Replace and secure all covers or elements of the system before applying power to this product.

Use only the specified voltage when operating this product. This product is designed to use 24 VDC. Always check whether your device is DC-powered before applying power.

Since this product is not equipped with a power switch, connect a power switch to the power supply.

Ground this product’s Functional Ground (FG) terminal.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

|

Note:

The SG (signal ground) and FG (functional ground) terminals are separated inside this product.

When the FG terminal is connected, ensure the wire is grounded. Not grounding this product can result in excessive electromagnetic interference (EMI).

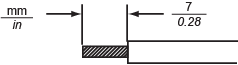

DC Power Cord Preparation

Make sure the ground wire is either the same or heavier gauge than the power wires.

Do not use aluminum wires in the power supply's power cord.

If the ends of the individual wires are not twisted correctly, the wires may create a short circuit.

The conductor type is solid or stranded wire.

Use copper wire rated for 75 °C (167 °F) or higher.

Use the SELV (Safety Extra-Low Voltage) circuit and LIM (Limited Energy) circuit for DC input.

Table: DC Power Cord Preparation

|

Item

|

Specification

|

|

Power cord diameter

|

0.75 to 2.5 mm

2

(18 to 13 AWG)

a

|

|

Conductor type

|

Solid or stranded wire

|

|

Conductor length

|

action_zoom_plus_stroke

|

|

Recommended driver

|

Flat-head screwdriver, size 0.6 x 3.5 mm (0.02 x 0.14 in)

|

a) For UL compatibility, use AWG 14 or AWG 13.

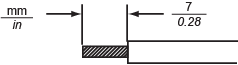

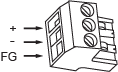

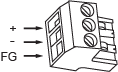

DC Power Supply Connector Specifications

Table: DC Power Supply Connector Specifications

|

|

Connection

|

Wire

|

|

action_zoom_plus_stroke

|

+

|

24 Vdc

|

|

-

|

0 Vdc

|

|

FG

|

Grounded terminal. Connect the FG terminal properly to the ground.

|

DC Power Supply Connection

Danger

Danger

|

|

SHORT CIRCUIT, FIRE, OR UNINTENDED EQUIPMENT OPERATION

Avoid excessive force on the power cable to help prevent accidental disconnection.

Securely attach power cables to an installation panel or cabinet.

Install and fasten this product on an installation panel or cabinet prior to connecting the power supply and communication lines.

Failure to follow these instructions will result in death or serious injury.

|

Improving Noise/Surge Resistance

This product’s power supply cord should not be bundled with or kept close to main circuit lines(high voltage, high current), power lines, or input/output lines, and their various systems should be kept separate. When power lines cannot be wired via a separate system, use shielded cables for input/output lines.

Make the power cord as short as possible, and twist the ends of the wires together (i.e. twisted-pair cabling) from close to the power supply unit.

If there is an excess amount of noise on the power supply line, reduce the noise with a noise filter before turning on the power.

Connect a surge protection device to handle power surges.

To increase noise resistance, attach a ferrite core to the power cable.

Power Supply Connections

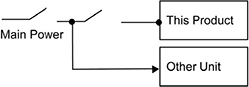

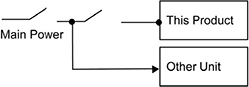

When supplying power to this product, connect the power as shown below.

action_zoom_plus_stroke

Use the SELV (Safety Extra-Low Voltage) circuit and LIM (Limited Energy) circuit for DC input.

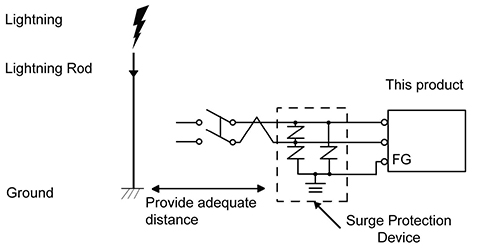

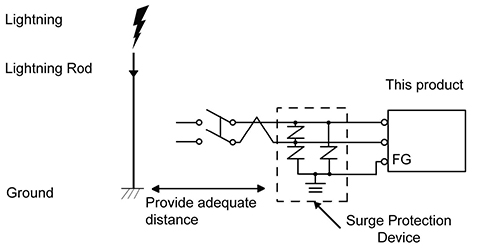

The following shows a surge protection device connection:

action_zoom_plus_stroke

Attach a surge protection device to help prevent damage to this product as a result of a lightning-induced power surge from a large electromagnetic field generated from a direct lightning strike. We also strongly recommend connecting the crossover grounding wire of this product to a position close to the ground terminal of the surge protection device. It is expected that there will be an effect on this product due to fluctuations in grounding potential when there is a large surge flow of electrical energy to the lightning rod ground at the time of a lightning strike. Provide adequate distance between the lightning rod grounding point and the surge protection device grounding point.

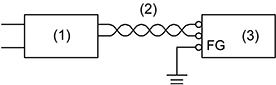

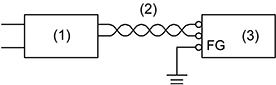

If the voltage variation is outside the prescribed range, connect a regulated power supply.

action_zoom_plus_stroke

1 Regulated power supply

2 Twisted-pair cord

3 This product

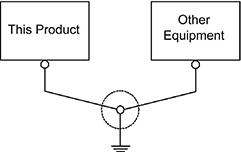

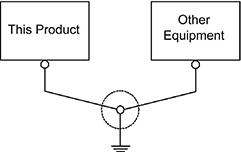

Exclusive Grounding

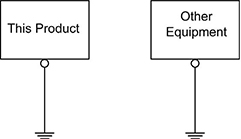

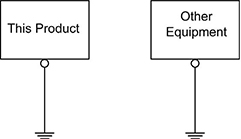

Always ground the FG (functional ground) terminal. Separate this product from the FG of other devices as shown below.

action_zoom_plus_stroke

Precautions

Check that the grounding resistance is 100 ohms or less.

a

The FG wire should have a cross-sectional area greater than 2 mm

2

(AWG14).

a

Create the connection point as close to this product as possible and make the wire as short as possible.

When using a long grounding wire, replace the thin wire with a thicker wire, and place it in a duct.

When connecting the FG (functional ground) and the SG (signal ground), ensure that no ground loop is formed.

a) Observe local codes and standards.

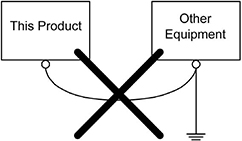

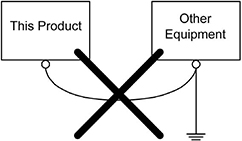

Common Grounding

Electromagnetic Interference (EMI) can be created if devices are improperly grounded. EMI cancause loss of communication. If exclusive grounding is not possible, use a common grounding point as shown in the configuration below. Do not use any other configuration for common grounding.

Correct grounding

action_zoom_plus_stroke

Incorrect grounding

action_zoom_plus_stroke

Grounding and Power for Systems with Operator Display

Grounding and Power for Systems with Operator Display

Operator Display Installation

Operator Display Installation

Installing Operator Display on a Panel

Installing Operator Display on a Panel

Warning

Warning

Danger

Danger