Operator Display is panel-mounted in equipment rooms using installation fasteners.

Operator Display is designed for use on flat surfaces of IP 65F, Type 1, Type 4X (indoor use only) and Type 13 enclosures.

Be aware of the following when building Operator Display into an end-user product:

The rear of Operator Display is not approved as an enclosure.

When building Operator Display into an end-user product, use an enclosure that satisfies standards as the end-user product’s overall enclosure.

Install Operator Display in an enclosure with mechanical rigidity.

Operator Display is not designed for outdoor use. UL certification obtained is for indoor use only.

Install and operate Operator Display with its front facing outward.

Installation Requirements

Read the specific security hardening recommendations before installing Operator Display.

Pour plus d'informations, voir Operator Display Hardening

.

Précaution

Précaution

|

|

RISK OF BURNING INJURY

Do not touch the bezel or rear chassis during operation.

Failure to follow these instructions can result in injury or equipment damage.

|

Before installing Operator Display, read the following list of installation requirements:

Check that the installation wall or cabinet surface is flat, in good condition and has no jagged edges. Metal reinforcing strips may be attached to the inside of the wall, near the panel-cut, to increase its rigidity.

Decide on the thickness of the enclosure wall, based on the level of strength required. Even if the installation wall thickness is within the recommended range for the panel cut dimensions, depending on wall’s material, size, and installation location of Operator Display and other devices, the installation wall could warp. To help prevent warping, the installation surface may need to be strengthened.

Check that the ambient air temperature and the ambient humidity are within their specified ranges in environmental specifications. When installing Operator Display in a cabinet or enclosure, the ambient air temperature is the cabinet’s or enclosure’s internal temperature.

Pour plus d'informations, voir Operator Display

.

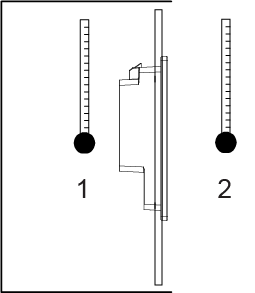

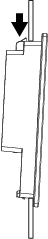

action_zoom_plus_stroke

1. Internal temperature

2. External temperature

Ensure that heat from surrounding equipment does not cause this product to exceed its standard operating temperature.

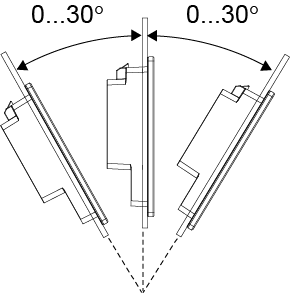

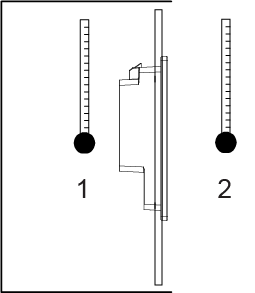

When installing this product in a slanted position, the product front should not be inclined by more than 30 degrees.

action_zoom_plus_stroke

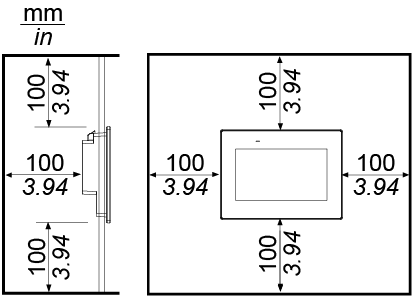

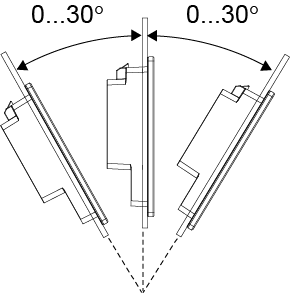

For easier maintenance, operation and improved ventilation, install this product at least 100 mm (3.94 in) away from adjacent structures and other equipment as shown in the following illustration:

action_zoom_plus_stroke

Pressure Differences

When applying and installing this product, it is important that steps are taken to help eliminate any pressure difference between the inside and the outside of the enclosure in which this product is mounted. Higher pressure inside the enclosure can cause delamination of the front membrane of the display. Even a small pressure difference inside the enclosure will act on the large area of the membrane and can result in sufficient force to delaminate the membrane and thus cause the failure of the touch capability. Pressure differences can often occur in applications where there are multiple fans and ventilators moving air at different rates in different rooms. Follow these techniques to help ensure that this product's function is not affected by this misapplication:

Seal all conduit connections inside of the enclosure, especially those that lead to other rooms that may be at a different pressure.

Where applicable, install a small weep hole at the bottom of the enclosure to allow equalization of the internal and external pressure.

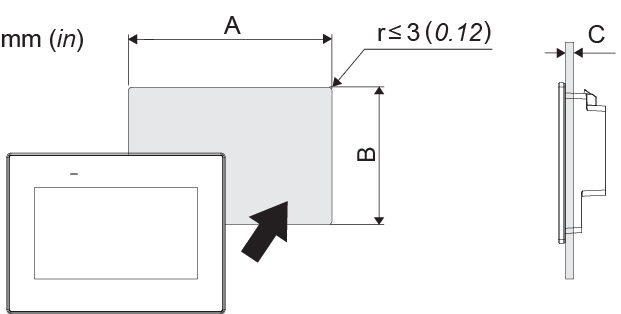

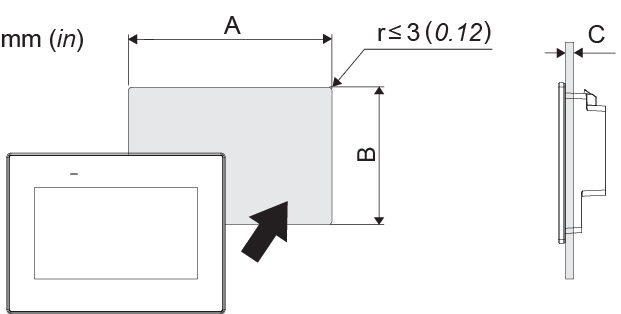

Panel Cut Dimensions

Specific measurements must be taken into consideration when preparing to install Operator Display on a panel.

action_zoom_plus_stroke

Figure :

Panel cut dimensions

|

A

|

B

|

C

|

|

190 mm (+1/0 mm)

(7.48 in [+0.04/0 in])

|

135 mm (+1/0 mm)

(5.31 in [+0.04/0 in])

|

1.6 to 5 mm

(0.06 to 0.2 in)

|

Operator Display Installation

Operator Display Installation

Installing Operator Display on a Panel

Installing Operator Display on a Panel

Précaution

Précaution

Avertissement

Avertissement