Log on to rate and give feedback

1

2

3

4

5

Log on to rate

0

How to

Products:

Operator Display

Functionalities:

Hardware

Product version:

3.3, 2022, 2023, 2024, 7.0

7/22/2021

Replacing the Installation Gasket on Operator Display

You replace the installation gasket to help ensure Operator Display is protected against dust and moisture.

To replace the installation gasket on Operator Display

Place this product on a flat, level surface, with the display face pointing down.

Remove the gasket from this product.

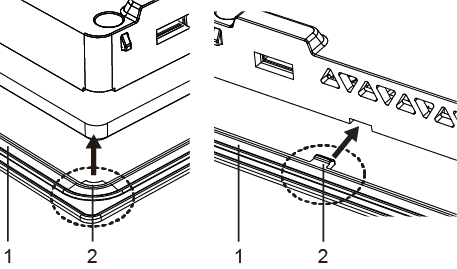

Attach the new gasket to this product. Insert the protrusions from the four corners of the gasket into the corresponding holes in the corners of this product. Refer to the figure on the right and insert the protrusions accordingly.

Note:When using a tool to insert the gasket, make sure the tool does not catch the rubber gasket and cause a tear.

action_zoom_plus_stroke

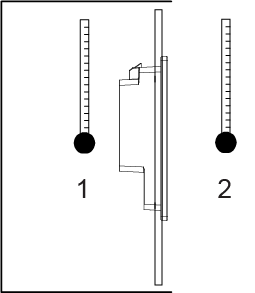

1. Installation gasket

2. Protruding point

Note:The gasket must be inserted correctly into the groove for moisture resistance for this product.

Operator Display Installation

Operator Display Installation

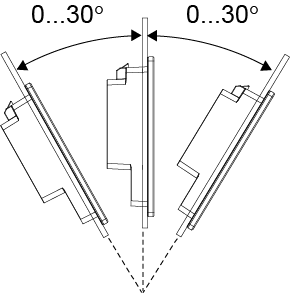

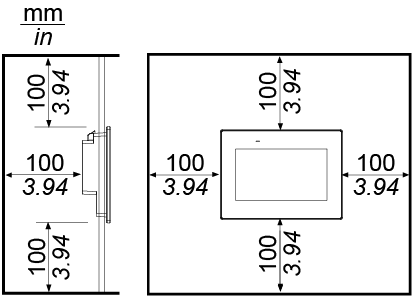

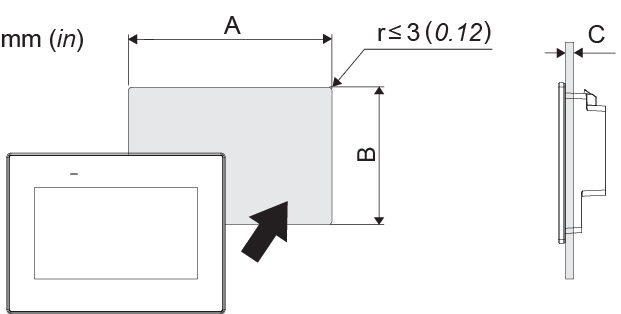

Installing Operator Display on a Panel

Installing Operator Display on a Panel

Caution

Caution