The RP-V incorporates an integral actuator and the device is designed for over-the-shaft damper installation.

RP-V models with built-in wireless chip must be professionally installed to comply with the following rules and regulations:

Part 15 of the Federal Communications Commission (FCC) rules

Innovation, Science and Economic Development Canada (ISED) licence-exempt Radio Standards Specifications (RSSs)

2014/53/EU Radio Equipment Directive (RED) of the European Union (EU)

S.I. 2017/1206 - Radio Equipment Regulations 2017 of the United Kingdom (UK)

For more information, see RP-V Regulatory Compliance and Approvals

.

The RP-V and its antenna(s) must be installed to provide a separation distance of at least 20 cm (8 in.) from all persons and must not be co-located or operating in conjunction with any other antenna or transmitter. Information on recommended RF exposure limits can be obtained from Health Canada's website,

www.canada.ca/en/health-canada

.

action_zoom_plus_stroke

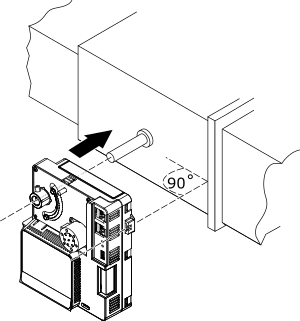

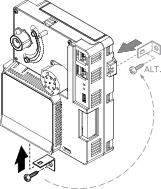

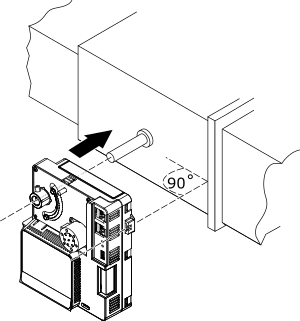

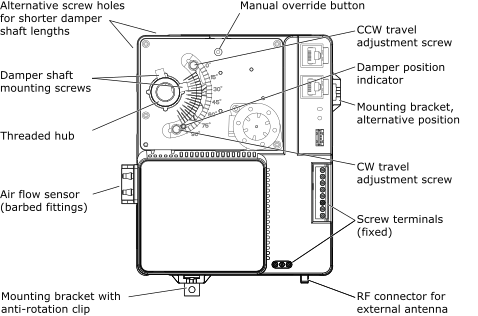

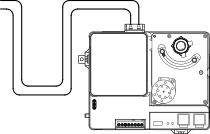

Figure:

RP-V installed over the damper shaft

The RP-V can be used with dampers that are opened in clockwise (CW) position as well as dampers opened in counter-clockwise (CCW) position. You use WorkStation or the EcoStruxure Building Commission mobile application to configure the RP-V actuator direction of rotation accordingly.

action_zoom_plus_stroke

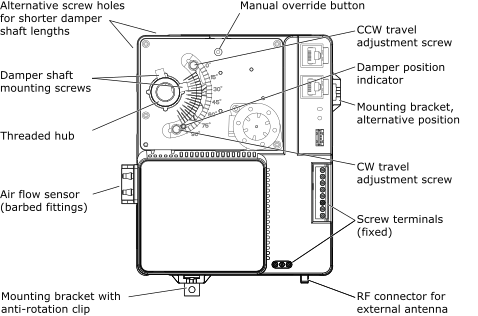

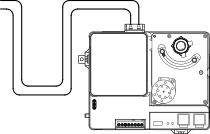

Figure:

RP-V components

The supported installation orientations do not differ between the different RP-V models:

RP-V-4A

RP-V-5A

RP-V-5C-M

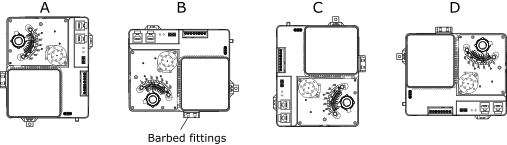

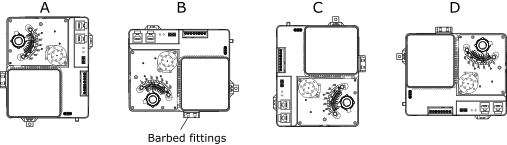

The RP-V is typically installed with the air flow sensor barbed fittings pointing down (orientation B in the figure below). The RP-V can also be installed with the barbed fittings pointing left (A), right (C), or up (D).

action_zoom_plus_stroke

Figure:

Supported installation orientations

With a downward extension, the available area around the damper shaft must measure:

160 mm (6 inches) down from the lower edge of the shaft,

120 mm (4.5 inches) to the right,

45 mm (1.75 inches) to the left, and

45 mm (1.75 inches) above the shaft.

Ensure that the location allows enough clearance for servicing.

The RP-V actuator is designed to be installed over a 12.7 mm (0.5 inch) diameter round damper shaft with a minimum of 54 mm (2.125 inches) exposed damper shaft length.

When the damper shaft diameter is less than 12.7 mm (0.5 inch), an adapter is required. An adapter with part number AM-135 can be ordered from Schneider Electric to enable installation on a 9.5 mm (0.375 inches) diameter damper shaft.

action_zoom_plus_stroke

Figure:

AM-135 damper shaft adapter

Important:

The cutout section of the shaft adapter must be positioned such that the damper shaft mounting screws are tightened against the damper shaft and not the adapter cylinder.

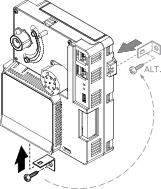

When the exposed damper shaft length is less than 54 mm (2.125 inches) but greater than 22.2 mm (0.875 inch), you move the damper shaft mounting screws from the actuator threaded hub to the alternative screw holes on the RP-V actuator.

action_zoom_plus_stroke

Figure:

Alternative position of the mounting screws for shorter damper shaft lengths

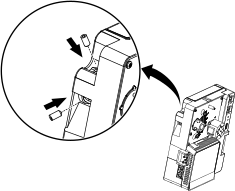

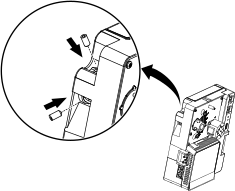

The RP-V also has two mounting brackets, which allow you to choose the mounting bracket that best accomodates the available access space in the VAV mounting area. You position the anti-rotation clip in the desired mounting bracket.

action_zoom_plus_stroke

Figure:

Two mounting brackets

The RP-V onboard air flow sensor is connected to an air velocity probe in the VAV box using two tubes. A dip in the tubing helps prevent moisture from entering the RP-V and damaging the air flow sensor. The dip should extend below the elevation of the barbed fittings. This applies to all RP-V orientations.

action_zoom_plus_stroke

Figure:

Tubing dip

|

Notice

|

|

AIR FLOW SENSOR DAMAGE

Do not expose the VAV controller's air flow sensor inputs to moisture during installation or operation.

Create a tubing dip that extends below the elevation of the barbed fittings to help prevent moisture from entering the VAV controller. This applies to all controller orientations.

Failure to follow these instructions can result in equipment damage.

|

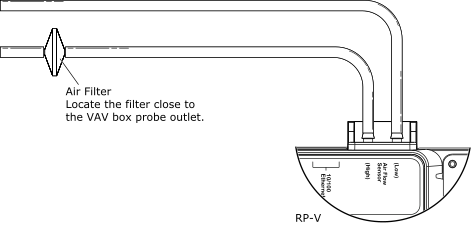

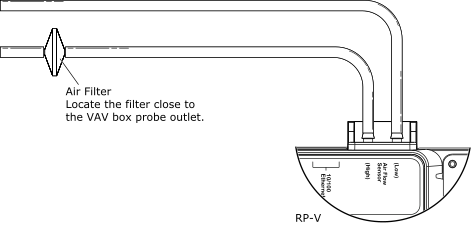

When operating in an unusually dusty environment, it is recommended to connect an in-line air filter (Schneider Electric part number 01-2100-272 or equivalent filter) on the high side pressure tube from the VAV box. The filter should be positioned close to the VAV box. The low flow of the sensor helps prevent most of the dust migration. The filter adds protection to help prevent dust from entering the velocity measurement tube in a dusty environment.

action_zoom_plus_stroke

Figure:

Air filter

When the RP-V is powered up for the first time, the RP-V software automatically performs an actuator travel and damper position calibration. The calibration operation drives the damper actuator in the close direction and registers the position when the actuator encounters the stop. The software then drives the actuator in the open direction and registers the position when the stop is encountered. The software uses that information to scale the 0 to 100% span. Mechanical obstructions hindering the damper actuator rotation during the calibration process can adversely affect the calibration results and thus the VAV damper operation. In that case, after removing the mechanical obstruction, you can manually run a recalibration.

For more information, see Configuring a Damper Command

.

Important:

Initial calibration of actuator travel and damper position is performed automatically when the RP-V is powered up for the first time. If you subsequently press the manual override button, you must recalibrate the RP-V manually.

For more information, see Configuring a Damper Command

.

|

Notice

|

|

VAV DAMPER NOT PROPERLY CONTROLLED

Ensure that the VAV controller is properly installed and secured prior to application of the 24 VAC power.

Ensure that the VAV controller damper actuator can rotate freely between the fully open and fully closed positions.

Failure to follow these instructions can result in the VAV damper not being properly controlled by the VAV controller.

|

The RP-V models have fixed screw terminals.

RP-V Device Installation

RP-V Device Installation

RP-V Screw Terminals

RP-V Screw Terminals

RP-V-4A Screw Terminals

RP-V-4A Screw Terminals

RP-V-5A Screw Terminals

RP-V-5A Screw Terminals

RP-V-5C-M Screw Terminals

RP-V-5C-M Screw Terminals

Wiring

Wiring

Powering Up an RP-V Controller

Powering Up an RP-V Controller

Caution

Caution