Especificaciones

SpaceLogic MP-C Pro

Introduction

SpaceLogic™ MP-C Pro is a multi-purpose, fully programmable, IP based field controller. The MP-C models offer a flexible mix of I/O point types that suit a wide range of HVAC applications. MP-C can either be used as a standalone BACnet/IP controller, BACnet/SC node, or as part of an EcoStruxure BMS with a SpaceLogic AS-P or AS-B server or an Enterprise Server as the parent server. The MP-C models support an optional display that provides insight and control of the inputs and outputs.

MP-C has the following features:

IP enabled with dual-port Ethernet switch

BACnet/SC node

Versatile onboard I/O point mix

Advanced monitoring

Configurable RS-485 port

Sensor bus for living space sensors

Modbus RTU subnetwork

Commission mobile application for commissioning of the controller before the BMS is in place

Full EcoStruxure Building Operation software support, providing efficient engineering tools

SpaceLogic Operator Display support

Upgrade with signed firmware

IP connectivity, flexible network topologies, and support for BACnet/SC applications

The BACnet/IP controllers are based on open protocols that simplify interoperability, IP configuration, and device management, and can be enabled as BACnet/SC nodes for increased cybersecurity:

IP addressing

BACnet/IP or BACnet/SC communications

DHCP for easy network configuration

The BACnet/IP controllers have a dual-port Ethernet switch, which enables flexible network topologies:

Star

Daisy chain

Rapid Spanning Tree Protocol (RSTP) ring

In a star topology, the controller and the parent EcoStruxure BMS server are individually connected to an Ethernet switch. Daisy-chain multiple controllers together to reduce installation time and cost. When using a ring network topology, in the event of a broken IP network or a non-operational controller, RSTP will enable rapid identification of the location of the detected error while maintaining communication with the controllers on either side of the break.

BACnet/SC (Secure Connect) support

The BACnet/IP controllers support BACnet/SC applications as a BACnet/SC node. This allows the controllers to be used in a BACnet/SC network, which allows secure transport of BACnet traffic and information between BACnet/SC devices over private and public networks without the need for BBMDs, VLANs, and VPNs, because the BACnet/SC protocol uses WebSocket technology and TLS 1.3 encryption. In addition, BACnet/SC uses certificate management to help ensure only those devices authorized to be on a BACnet/SC network can operate on that network.

Models with a versatile mix of I/O points

MP-C comes in five models with different I/O point count and a versatile mix of I/O point types that match a wide variety of applications. The universal inputs/outputs are highly flexible and can be configured as either inputs or outputs.

|

I/O Point Types |

MP-C-15A |

MP-C-18A |

MP-C-18B |

MP-C-24A |

MP-C-36A |

|

Universal I/O Type Ub |

8 |

10 |

10 |

16 |

20 |

|

Universal I/O Type Uc |

- |

- |

- |

4 |

8 |

|

Triac outputs |

6 |

4 |

8 |

- |

- |

|

Relay outputs Form A |

- |

3 |

- |

4 |

8 |

|

High power relay outputs Form A |

1 |

1 |

- |

- |

- |

|

Configurations |

Universal I/O Type Ub |

Universal I/O Type Uc |

Triac Outputs |

Relay Outputs Form A |

High Power Relay Outputs Form A |

|

Digital inputs |

yes |

yes |

- |

- |

- |

|

Counter inputs |

yes |

yes |

- |

- |

- |

|

Supervised inputs |

yes |

yes |

- |

- |

- |

|

Voltage inputs (0 to 10 VDC) |

yes |

yes |

- |

- |

- |

|

Current inputs (0 to 20 mA) |

yes |

yes |

- |

- |

- |

|

Temperature inputs |

yes |

yes |

- |

- |

- |

|

Resistive inputs |

yes |

yes |

- |

- |

- |

|

2-wire RTD temperature inputs |

yes |

yes |

- |

- |

- |

|

Voltage outputs (0 to 10 VDC) |

yes |

yes |

- |

- |

- |

|

Current outputs (0 to 20 mA) |

- |

yes |

- |

- |

- |

|

Digital outputs |

- |

- |

yes |

yes |

yes |

|

Digital pulsed outputs |

- |

- |

yes |

yes |

yes |

|

PWM outputs |

- |

- |

yes |

yes |

yes |

|

Tristate outputs |

- |

- |

yes |

yes |

- |

|

Tristate pulsed outputs |

- |

- |

yes |

yes |

- |

The universal inputs/outputs are ideal for any mix of temperature, pressure, flow, status points, and similar point types in a building control system.

As counter inputs, the universal inputs/outputs are commonly used in energy metering applications. As RTD inputs, they are ideal for temperature points in a building control system. As supervised inputs, they are used for security applications where it is critical to know whether or not a wire has been cut or shorted. These events provide a separate indication of alarms and events in the system.

For all analog inputs, maximum and minimum levels can be defined to automatically detect over-range and under-range values.

The universal inputs/outputs can also be used as voltage outputs or current outputs (Uc only), without the need for external bias resistors. Therefore, the universal inputs/outputs support a wide range of devices, such as actuators.

The triac outputs can be used in many applications to switch 24 VAC on or off for external loads such as actuators, relays, or indicators. The triac outputs are isolated from the controller. Triacs are silent and are not adversely affected by relay contact wear.

The relay outputs support digital Form A point types. The Form A relays are designed for direct load applications.

MP-C-15A and MP-C-18A have a high power relay output, which is ideal for switching loads of up to 12 A, such as electrical heating elements.

For applications that require more I/O resources, the SpaceLogic IP-IO modules provide a versatile mix of I/O points for any application. For more information, see the SpaceLogic IP-IO Specification Sheet.

Advanced monitoring

The BACnet/IP controllers support local trends, schedules, and alarms, enabling local operation when the controller is offline or used in standalone applications.

With user-defined fallback values, the I/O module outputs will be in a predictable state in cases of network disruption.

The battery-free power backup of the memory and real-time clock helps prevent data loss and allows seamless and quick recovery after a power disruption.

All MP-C models can be equipped with the MP-C Display add-on module, which features an LCD display and five keys. With this module, you can manually override analog and digital outputs for testing, commissioning, and maintenance of equipment connected to the outputs. The module's dedicated processing power helps to ensure reliable override for maintenance applications. The override status can be viewed in EcoStruxure Building Operation WorkStation and WebStation, enabling more precise monitoring and control.

In WorkStation, you update the firmware of multiple BACnet/IP controllers at the same time and with minimum down time. The EcoStruxure BMS server keeps track of the installed firmware to support backup, restore, and replacement of the controllers and sensors. The server can host controllers of different firmware versions.

Configurable RS-485 port

The MP-C controller has one configurable RS-485 port, which can be configured to support two different types of networks:

Sensor bus

Modbus network

Sensor bus for living space sensors

The BACnet/IP controllers provide an interface designed for the SpaceLogic Sensor family of living space sensors. The SpaceLogic Sensor devices offer an efficient way to sense the temperature, humidity, CO 2 , and occupancy in a room. The SpaceLogic Sensor devices are available with different combinations of sensor types and various covers and user interface options, such as touchscreen, setpoint and override buttons, and blank covers. For more information, see the SpaceLogic Sensors - SXWS Sensors for MP and RP IP Controllers - Specification Sheet.

The sensor bus provides both power and communications for up to four sensors that are daisy-chained using standard Cat 5 (or higher) cables. The maximum number of sensors that can be connected to a controller varies depending on the sensor model and the combination of cover and sensor base type:

Blank covers: Up to four sensors of any combination of sensor base types

3-button and touchscreen covers:

Up to two sensor bases with CO 2 option

Up to four sensor bases without CO 2 option

SpaceLogic LCD temperature sensors: Up to four sensors are supported

The maximum total length of the sensor bus is 61 m (200 ft). For more information, see the SpaceLogic Sensors - SXWS Sensors for MP and RP IP Controllers - Specification Sheet.

The RS-485 Power Adapter can be used to supply 24 VDC power to the MP controller sensor bus so that the maximum number of sensor bases with CO 2 option can be increased from two to four sensor bases. The adapter can be ordered from Schneider Electric. For more information, see section the RS-485 Adapters Specification Sheet.

Modbus RTU subnetwork

The MP-C Modbus RTU (RS-485) subnetwork allows standard Modbus devices to be connected to the controller.

The Modbus RTU protocol is used for the communication. The MP controller acts as the Modbus client and the connected devices act as servers.

For connection to Modbus devices, it is recommended to use the non-isolated RS-485 adapter to provide screw termination. The adapter converts an RS-485 RJ45 interface to screw terminals. The adapter can be ordered from Schneider Electric. For more information, see the RS-485 Adapters Specification Sheet.

To connect the adapter, it is recommended that you use a Cat 5 (or higher) UTP cable with eight conductors and RJ45 connectors. The cable should be rated for the target environment and have a maximum length of 0.3 m (12 in.). The cable is not included and needs to be purchased separately.

The maximum number of Modbus devices that can be connected to an MP controller depends on the type of Modbus device and the number of Modbus registers.

The MP controller Modbus network supports up to 20 connected Modbus devices with the following restrictions:

Maximum of 1,000 Modbus registers per network

64-bit Modbus registers are supported, which can be used in energy metering.

Maximum total length of the Modbus network is 72 m (236 ft).

The Modbus devices require a separate power supply unit.

Modbus device types are pre-configured Modbus applications for quick and easy Modbus device integration in EcoStruxure Building Operation solutions. For information on the Modbus devices supported using Modbus device types, see the document EcoStruxure Building - Modbus Device Integration - Supported Device Brochure.

Commission mobile application

The Commission mobile application is designed for local configuration, field deployment, and commissioning of BACnet/IP controllers. The mobile application reduces the commissioning time, allows flexibility in project execution, and minimizes dependencies on network infrastructure.

The mobile application is designed for use with Android, Apple (iOS), and Microsoft Windows 10 and Windows 11 devices. For more information, see the EcoStruxure Building Commission Specification Sheet.

Using the Commission mobile application, you can connect to one or many BACnet/IP controllers. You can connect to a single BACnet/IP controller using the SpaceLogic Bluetooth Adapter connected to a SpaceLogic Sensor. Using a wireless access point or a network switch, you can connect to a network of BACnet/IP controllers on the local IP network.

With the Commission mobile application, you can easily discover BACnet/IP controllers on the IP network. You can change the configuration of each controller, including the BACnet and IP network settings, location, and parent server. To save engineering time, you can save common device settings and then reuse them for controllers of the same model.

The Commission mobile application does not require an EcoStruxure BMS server or a network infrastructure to be in place. You can use the mobile application to load the controller application directly into the local BACnet/IP controller and deploy the controller. The controller application can be created offline using Project Configuration Tool or WorkStation. You can also perform an I/O checkout to verify that the controller's I/O points are configured, wired, and operating correctly.

Full EcoStruxure Building Operation software support

The power of the BACnet/IP controller is fully realized when it is part of an EcoStruxure BMS, which provides the following benefits:

WorkStation/WebStation interface

Script and Function Block programming options

Device discovery

Engineering efficiency

Preconfigured BMS applications for HVAC

WorkStation and WebStation provide a consistent user experience regardless of which EcoStruxure BMS server the user is logged on to. The user can log on to the parent EcoStruxure BMS server to engineer, commission, supervise, and monitor the BACnet/IP controller and its I/O as well as its attached SpaceLogic Sensor devices. For more information, see the WorkStation and WebStation specification sheets.

Unique to the industry, the BACnet/IP controllers have both Script and Function Block programming options. This flexibility assures that the best programming method can be selected for the application. Existing programs can easily be reused between the EcoStruxure BMS server and the controller.

The enhanced Device Discovery in WorkStation enables you to easily identify BACnet/IP controllers on a BACnet network and to associate the controllers with their parent server.

The engineering and maintenance of BACnet/IP controllers can be done very efficiently using the EcoStruxure Building Operation reusability features. With these features, you can create library items (Custom Types) for a complete controller application that contains programs and all necessary objects such as trends, alarms, and schedules. The controller application in the Custom Types library is reusable across all controllers of the same model. You can use the controller application as a base for creating new controllers intended for similar applications. You can then edit the controller application, and the changes are automatically replicated to all controllers, while each controller keeps its local values.

WorkStation supports both online and offline engineering of BACnet/IP controllers. You can make the configuration changes online or use database mode to make the changes offline. In database mode, the changes are saved to the EcoStruxure Building Operation database so that you can apply the changes to the controllers later.

Project Configuration Tool enables you to perform all the engineering off site, without the need for physical hardware, which minimizes the time you need to spend on site. You can run the EcoStruxure BMS servers virtually and engineer the BACnet/IP controllers before you deploy your server and controller applications to the servers and controllers on site. For more information, see the Project Configuration Tool specification sheet.

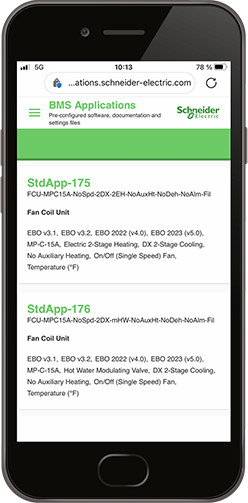

To improve engineering efficiency and standardize engineering practices, fully designed and tested controller applications are available at bms-applications.schneider-electric.com for use with the MP controllers. This library contains applications for different MP controller models and application types, such as fan coil units, VAV, and ceiling solutions. These preconfigured controller applications are packages that include all software programs, and for example graphics, alarms, and documentation such as functional specifications and I/O wiring schedules, that are needed for your projects. The online repository can be accessed using common web browsers on Windows PCs as well as mobile devices running Apple iOS 11.3 (or later) and Android 6.0 Marshmallow (or later).

SpaceLogic Operator Display support

SpaceLogic Operator Display is an easy HMI based on the BACnet B-OD profile. It can interface and interact with up to seven SpaceLogic BACnet/IP controllers in a small BMS without an EcoStruxure BMS server. It features a large 7-inch color touch screen and a preloaded application. It is easy to install and use and does not require any programming. Built for the equipment room, the panel-mounted SpaceLogic Operator Display offers an ingress protection rating of IP65, which makes it both dust-tight and protected from low-pressure water jets. For more information, see the SpaceLogic Operator Display Specification Sheet.

Upgrade with signed firmware

Using digitally signed firmware provides more secure upgrading of the device. During an upgrade, the device verifies that the firmware is authentic and uncompromised Schneider Electric firmware. If the device detects discrepancies in the authenticity or integrity of the firmware, it will reject the upgrade. Once the device is upgraded with signed firmware, all upgrades thereafter must be with a signed firmware version.

|

Product |

Part number |

|

MP-C-15A

|

SXWMPC15A10001

|

|

MP-C-18A

|

SXWMPC18A10001

|

|

MP-C-18B

|

SXWMPC18B10001

|

|

MP-C-24A

|

SXWMPC24A10001

|

|

MP-C-36A

|

SXWMPC36A10001

|

|

MP-C-15A-BAA a |

SXWMPC15A10A01

|

|

MP-C-18A-BAA a |

SXWMPC18A10A01

|

|

MP-C-18B-BAA a |

SXWMPC18B10A01

|

|

MP-C-24A-BAA a |

SXWMPC24A10A01

|

|

MP-C-36A-BAA a |

SXWMPC36A10A01

|

|

MP-C-15A-SMK b |

SXWMPC15A1S001

|

|

MP-C-18A-SMK b |

SXWMPC18A1S001

|

|

MP-C-18B-SMK b |

SXWMPC18B1S001

|

|

MP-C-24A-SMK b |

SXWMPC24A1S001

|

|

MP-C-36A-SMK b |

SXWMPC36A1S001

|

- Buy American Act (BAA) compliant. MP-C-15A-BAA and MP-C-36A-BAA are also included in BAA compliant bundles that include either the MP-C-15A-BAA controller and MP-C-BAA DISPLAY or the MP-C-36A-BAA controller and MP-C-BAA DISPLAY. The bundles can be ordered using the part number SXWMPC15AB10A01 for the MP-C-15A-BAA bundle or SXWMPC36AB10A01 for the MP-C-36A-BAA bundle.

- Approved for use in UL 864 smoke control systems. The smoke control (SMK) models are shipped with a validated UL 864 software version, which can differ from the latest released software. For information on the approved software revisions for the device when used in UL 864 smoke control systems, see the Smoke Control System Approved Software Revisions - EcoStruxure Building Management document, 01-16001-XX-en.

|

Product |

Part number |

|

MP-C DISPLAY a (MP-C override display module) |

SXWMPCDSP10001

|

|

MP-C-BAA DISPLAY b (MP-C BAA override display module) |

SXWMPCDSP10A01

|

|

Spare terminal blocks for all MP-C models

(4 x 3-pin, 1 x 4-pin, 7 x 6-pin, 2 x 8-pin terminal blocks)

|

SXWMPCCON10001

|

|

DIN-RAIL-CLIP, DIN-rail end clip

package of 25 pieces

|

SXWDINEND10001

|

|

Non-isolated RS-485 adapter c |

SXWNISORS48510001

|

|

RS-485 power adapter c |

SXWNISORS485P10001

|

|

SpaceLogic Bluetooth Adapter c |

SXWBTAECXX10001

|

- Approved for use in UL 864 smoke control systems.

- MP-C-BAA DISPLAY is included in Buy American Act (BAA) compliant bundles along with either the MP-C-15A-BAA or MP-C-36A-BAA controller. MP-C-BAA DISPLAY can only be ordered using the part number for the MP-C-15A-BAA bundle (SXWMPC15AB10A01) or MP-C-36A-BAA bundle (SXWMPC36AB10A01). MP-C-BAA DISPLAY does not differ from MP-C DISPLAY in terms of hardware and functionality.

- The RS-485 adapters and the Bluetooth adapter are not available in Buy American Act (BAA) compliant variants.

For more information on part numbers for Network Connectivity Accessories, see the Para obtener más información, consulte Product Selection Guide - EcoStruxure Building ..

Especificaciones

| AC input | |||||||||||||

Nominal voltage

|

24 VAC

|

||||||||||||

Operating voltage range

|

+/- 20 %

|

||||||||||||

Frequency

|

50/60 Hz

|

||||||||||||

Maximum power consumption (MP-C-15A, -18A, -18B)

|

22 VA

|

||||||||||||

Maximum power consumption (MP-C-24A)

|

28 VA

|

||||||||||||

Maximum power consumption (MP-C-36A)

|

33 VA

|

||||||||||||

Power input protection

|

MOV suppression and internal fuse

|

||||||||||||

| DC input | |||||||||||||

Nominal voltage

|

24 to 30 VDC

|

||||||||||||

Operating voltage range

|

21 to 33 VDC

|

||||||||||||

Maximum power consumption (MP-C-15A, -18A, -18B)

|

12 W

|

||||||||||||

Maximum power consumption (MP-C-24A)

|

15 W

|

||||||||||||

Maximum power consumption (MP-C-36A)

|

18 W

|

||||||||||||

Power input protection

|

MOV suppression and internal fuse

|

||||||||||||

| Environment | |||||||||||||

Ambient temperature, operating

|

0 to 50 °C (32 to 122 °F) at normal operation

a

|

||||||||||||

-40 to +60 °C (-40 to +140 °F) for rooftop applications, horizontal installation only

a

|

|||||||||||||

| a) MP-C Display has an operating temperature range of -30 to +60 °C (-22 to +140 °F). | |||||||||||||

Ambient temperature, storage

|

-40 to +70 °C (-40 to +158 °F)

|

||||||||||||

Maximum humidity

|

95 % RH non-condensing

|

||||||||||||

| Material | |||||||||||||

Plastic flame rating

|

UL94 V-0

|

||||||||||||

Ingress protection rating

|

IP 20

|

||||||||||||

| Mechanical | |||||||||||||

Dimensions (MP-C-15A, -18A, -18B)

|

153 W x 110 H x 64 D mm (6.0 W x 4.3 H x 2.5 D in.)

|

||||||||||||

|

|||||||||||||

Dimensions (MP-C-24A, -36A)

|

234 W x 110 H x 64 D mm (9.2 W x 4.3 H x 2.5 D in.)

|

||||||||||||

|

|||||||||||||

Weight, MP-C-15A

|

|||||||||||||

Including terminal blocks

|

0.358 kg (0.789 lb)

|

||||||||||||

Weight, MP-C-18A

|

|||||||||||||

Including terminal blocks

|

0.371 kg (0.818 lb)

|

||||||||||||

Weight, MP-C-18B

|

|||||||||||||

Including terminal blocks

|

0.361 kg (0.796 lb)

|

||||||||||||

Weight, MP-C-24A

|

|||||||||||||

Including terminal blocks

|

0.495 kg (1.091 lb)

|

||||||||||||

Weight, MP-C-36A

|

|||||||||||||

Including terminal blocks

|

0.547 kg (1.206 lb)

|

||||||||||||

Recommended installation

|

DIN rail or flat surface in a cabinet

a

|

||||||||||||

| a) It is recommended to install the device in an enclosure (cabinet), unless local regulations allow an exception. | |||||||||||||

Terminal blocks

|

Removable

|

||||||||||||

| Compatibility | |||||||||||||

EcoStruxure BMS server communication

|

|||||||||||||

EcoStruxure Building Operation

|

version 2.0.4 and later

|

||||||||||||

Modbus RTU subnetwork support

|

|||||||||||||

EcoStruxure Building Operation software

|

version 5.0.1 and later

|

||||||||||||

BACnet/SC network support

|

|||||||||||||

EcoStruxure Building Operation

|

version 6.0.1 and later

|

||||||||||||

EcoStruxure Building Management Smoke Control System

a

|

|||||||||||||

EcoStruxure Building Operation

|

For information, see the Smoke Control System Approved Software Revisions - EcoStruxure Building Management document, 01-16001-XX-en.

|

||||||||||||

| a) Applies to the Smoke Control (SMK) models. | |||||||||||||

| Agency compliances | |||||||||||||

Emission

|

RCM; BS/EN 61000-6-3; BS/EN IEC 63044-5-2; FCC Part 15, Sub-part B, Class B

|

||||||||||||

Immunity

|

BS/EN 61000-6-2; BS/EN IEC 63044-5-3

|

||||||||||||

Safety standards

|

BS/EN 60730-1; BS/EN 60730-2-11; BS/EN IEC 63044-3; UL 916 C-UL US Listed

|

||||||||||||

Smoke control product safety

a

|

UL 864

|

||||||||||||

| a) Applies to the Smoke Control (SMK) models and MP-C DISPLAY module. For specifications and information on the restrictions that apply to the SMK models and display module when used in UL 864 smoke control systems, see the EcoStruxure Building Management - Smoke Control System Design Guide, 04-16014-XX-en. | |||||||||||||

| Real-time clock | |||||||||||||

Accuracy, at 25 °C (77 °F)

|

+/-1 minute per month

|

||||||||||||

Backup time, at 25 °C (77 °F)

|

7 days minimum

|

||||||||||||

| Communication ports | |||||||||||||

Ethernet

|

Dual 10/100BASE-TX (RJ45), IEEE 802.3 compliant

|

||||||||||||

USB

|

1 USB 2.0 device port (mini-B)

|

||||||||||||

1 USB 2.0 host port (type-A), 5 VDC, 2.5 W

|

|||||||||||||

RS-485 port Com A

|

24 VDC, 2 W, RS-485 (RJ45)

|

||||||||||||

Transient voltage suppressors on communication and power signals

|

|||||||||||||

| RS-485 transceiver characteristics | |||||||||||||

Transceiver type

|

Failsafe

|

||||||||||||

Non-isolated

|

|||||||||||||

External biasing

|

None required

|

||||||||||||

Total Unit Load (UL) per device

|

Maximum 0.5 UL

|

||||||||||||

| Communications | |||||||||||||

BACnet

|

BACnet/IP, port configurable, default 47808

|

||||||||||||

BACnet/SC, port configurable, no default port

|

|||||||||||||

BTL B-AAC (BACnet Advanced Application Controller), B-GW (BACnet Gateway)

a

|

|||||||||||||

| a) See the BTL Product Catalog for up-to-date details on BTL listed firmware revisions on BACnet International's home page. | |||||||||||||

| CPU | |||||||||||||

Frequency

|

500 MHz

|

||||||||||||

Type

|

ARM Cortex-A7 dual-core

|

||||||||||||

DDR3 SDRAM

|

128 MB

|

||||||||||||

NOR flash memory

|

32 MB

|

||||||||||||

Memory backup

|

128 kB, FRAM, non-volatile

|

||||||||||||

| MP-C Display (Optional) | |||||||||||||

Removable

|

No

|

||||||||||||

Dimensions

|

74 W x 46 H x 24 D mm (2.9 W x 1.8 H x 0.9 D in.)

|

||||||||||||

|

|||||||||||||

Display size

|

36 W x 17 H mm (1.4 W x 0.7 H in.)

|

||||||||||||

Display resolution

|

128 x 64 pixels

|

||||||||||||

Display type

|

FSTN monochrome LCD, white color transflective backlight

|

||||||||||||

Power consumption

|

max. 0.15 W (45 mA at 3.3 V)

|

||||||||||||

Ambient temperature, operating

|

-30 to +60 °C (-22 to +140 °F)

|

||||||||||||

Ambient temperature, storage

|

-40 to +70 °C (-40 to +158 °F)

|

||||||||||||

Maximum humidity

|

95 % RH non-condensing

|

||||||||||||

Weight

|

0.035 kg (0.077 lb)

|

||||||||||||

Compliance with standards

|

EN ISO 16484-2

|

||||||||||||

| Universal inputs/outputs, Ub and Uc | |||||||||||||

Channels, MP-C-15A

|

8 Ub, Ub1 to Ub8

|

||||||||||||

Channels, MP-C-18A

|

10 Ub, Ub1 to Ub10

|

||||||||||||

Channels, MP-C-18B

|

10 Ub, Ub1 to Ub10

|

||||||||||||

Channels, MP-C-24A

|

16 Ub, Ub1 to Ub16

|

||||||||||||

4 Uc, Uc1 to Uc4

|

|||||||||||||

Channels, MP-C-36A

|

20 Ub, Ub1 to Ub20

|

||||||||||||

8 Uc, Uc1 to Uc8

|

|||||||||||||

Absolute maximum ratings

|

-0.5 to +24 VDC

|

||||||||||||

A/D converter resolution

|

16 bits

|

||||||||||||

Universal input/output protection

|

Transient voltage suppressor on each universal input/output

|

||||||||||||

| Digital inputs | |||||||||||||

Range

|

Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

|

||||||||||||

Minimum pulse width

|

150 ms

|

||||||||||||

| Counter inputs | |||||||||||||

Range

|

Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

|

||||||||||||

Minimum pulse width

|

20 ms

|

||||||||||||

Maximum frequency

|

25 Hz

|

||||||||||||

| Supervised inputs | |||||||||||||

5 V circuit, 1 or 2 resistors

|

|||||||||||||

Monitored switch combinations

|

Series only, parallel only, and series and parallel

|

||||||||||||

Resistor range

|

1 to 10 kohm

|

||||||||||||

| For a 2-resistor configuration, each resistor must have the same value +/- 5 % | |||||||||||||

| Voltage inputs | |||||||||||||

Range

|

0 to 10 VDC

|

||||||||||||

Accuracy

|

+/-(7 mV + 0.2 % of reading)

|

||||||||||||

Resolution

|

1.0 mV

|

||||||||||||

Impedance

|

100 kohm

|

||||||||||||

| Current inputs | |||||||||||||

Range

|

0 to 20 mA

|

||||||||||||

Accuracy

|

+/-(0.01 mA + 0.4 % of reading)

|

||||||||||||

Resolution

|

1 μA

|

||||||||||||

Impedance

|

47 ohm

|

||||||||||||

| Resistive inputs | |||||||||||||

10 ohm to 10 kohm accuracy

|

+/-(7 + 4 x 10

-3

x R) ohm

|

||||||||||||

| R = Resistance in ohm | |||||||||||||

10 kohm to 60 kohm accuracy

|

+/-(4 x 10

-3

x R + 7 x 10

-8

x R

2

) ohm

|

||||||||||||

| R = Resistance in ohm | |||||||||||||

| Temperature inputs (thermistors) | |||||||||||||

Range

|

-50 to +150 °C (-58 to +302 °F)

|

||||||||||||

| Supported thermistors | |||||||||||||

Honeywell

|

20 kohm

|

||||||||||||

Type I (Continuum)

|

10 kohm

|

||||||||||||

Type II (I/NET)

|

10 kohm

|

||||||||||||

Type III (Satchwell)

|

10 kohm

|

||||||||||||

Type IV (FD)

|

10 kohm

|

||||||||||||

Type V (FD w/ 11k shunt)

|

Linearized 10 kohm

|

||||||||||||

Satchwell D?T

|

Linearized 10 kohm

|

||||||||||||

Johnson Controls

|

2.2 kohm

|

||||||||||||

Xenta

|

1.8 kohm

|

||||||||||||

Balco

|

1 kohm

|

||||||||||||

| Measurement accuracy | |||||||||||||

20 kohm

|

-50 to -30 °C: +/-1.5 °C (-58 to -22 °F: +/-2.7 °F)

|

||||||||||||

-30 to 0 °C: +/-0.5 °C (-22 to +32 °F: +/-0.9 °F)

|

|||||||||||||

0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

|

|||||||||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||||||||

10 kohm, 2.2 kohm, and 1.8 kohm

|

-50 to -30 °C: +/-0.75 °C (-58 to -22 °F: +/-1.35 °F)

|

||||||||||||

-30 to +100 °C: +/-0.2 °C (-22 to +212 °F: +/-0.4 °F)

|

|||||||||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||||||||

Linearized 10 kohm

|

-50 to -30 °C: +/-2.0 °C (-58 to -22 °F: +/-3.6 °F)

|

||||||||||||

-30 to 0 °C: +/-0.75 °C (-22 to +32 °F: +/-1.35 °F)

|

|||||||||||||

0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

|

|||||||||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||||||||

1 kohm

|

-50 to +150 °C: +/-1.0 °C (-58 to +302° F: +/-1.8 °F)

|

||||||||||||

| RTD temperature inputs | |||||||||||||

Supported RTDs

|

Pt1000, Ni1000, and LG-Ni1000

|

||||||||||||

| Pt1000 | |||||||||||||

Sensor range

|

-50 to +150 °C (-58 to +302 °F)

|

||||||||||||

|

|||||||||||||

| Ni1000 | |||||||||||||

Sensor range

|

-50 to +150 °C (-58 to +302 °F)

|

||||||||||||

|

|||||||||||||

| LG-Ni1000 | |||||||||||||

Sensor range

|

-50 to +150 °C (-58 to +302 °F)

|

||||||||||||

|

|||||||||||||

| RTD temperature wiring | |||||||||||||

Maximum wire resistance

|

20 ohm/wire (40 ohm total)

|

||||||||||||

Maximum wire capacitance

|

60 nF

|

||||||||||||

| The wire resistance and capacitance typically corresponds to a 200 m wire. | |||||||||||||

| Voltage outputs | |||||||||||||

Range

|

0 to 10 VDC

|

||||||||||||

Accuracy

|

+/-60 mV

|

||||||||||||

Resolution

|

10 mV

|

||||||||||||

Minimum load resistance

|

5 kohm

|

||||||||||||

Load range

|

-1 to +2 mA

|

||||||||||||

| Current outputs (Uc only) | |||||||||||||

Range

|

0 to 20 mA

|

||||||||||||

Accuracy

|

+/-0.2 mA

|

||||||||||||

Resolution

|

21 µA

|

||||||||||||

Load range

|

0 to 650 ohm

|

||||||||||||

| Relay outputs, DO | |||||||||||||

Channels, MP-C-15A

|

0

|

||||||||||||

Channels, MP-C-18A

|

3, DO5 to DO7

|

||||||||||||

Channels, MP-C-18B

|

0

|

||||||||||||

Channels, MP-C-24A

|

4, DO1 to DO4

|

||||||||||||

Channels, MP-C-36A

|

8, DO1 to DO8

|

||||||||||||

Contact rating

|

250 VAC/30 VDC, 2 A, Pilot Duty (C300)

|

||||||||||||

Switch type

|

Form A Relay

|

||||||||||||

Single Pole Single Throw

|

|||||||||||||

Normally Open

|

|||||||||||||

Isolation contact to system ground

|

3000 VAC

|

||||||||||||

Cycle life (Resistive load)

|

At least 100,000 cycles

|

||||||||||||

Minimum pulse width

|

100 ms

|

||||||||||||

| High power relay outputs, DO | |||||||||||||

Channels, MP-C-15A

|

1, DO7

|

||||||||||||

Channels, MP-C-18A

|

1, DO8

|

||||||||||||

Channels, MP-C-18B

|

0

|

||||||||||||

Channels, MP-C-24A

|

0

|

||||||||||||

Channels, MP-C-36A

|

0

|

||||||||||||

Contact rating

|

250 VAC/24 VDC, 12 A, Pilot Duty (B300)

|

||||||||||||

Switch type

|

Form A Relay

|

||||||||||||

Single Pole Single Throw

|

|||||||||||||

Normally Open

|

|||||||||||||

Isolation contact to system ground

|

5000 VAC

|

||||||||||||

Cycle life (Resistive load)

|

At least 100,000 cycles

|

||||||||||||

Minimum pulse width

|

100 ms

|

||||||||||||

| Triac outputs, DO | |||||||||||||

Channels, MP-C-15A

|

6, DO1 to DO6

|

||||||||||||

Channels, MP-C-18A

|

4, DO1 to DO4

|

||||||||||||

Channels, MP-C-18B

|

8, DO1 to DO8

|

||||||||||||

Channels, MP-C-24A

|

0

|

||||||||||||

Channels, MP-C-36A

|

0

|

||||||||||||

Output rating (for each triac output)

|

Max. 0.5 A

|

||||||||||||

Voltage

|

24 VAC +/-20 %

|

||||||||||||

Commons

|

COM1 for DO1 and DO2 (on MP-C-15A, -18A, -18B)

|

||||||||||||

COM2 for DO3 and DO4 (on MP-C-15A, -18A, -18B)

|

|||||||||||||

COM3 for DO5 and DO6 (on MP-C-15A, -18B)

|

|||||||||||||

COM4 for DO7 and DO8 (on MP-C-18B only)

|

|||||||||||||

| The common terminals can be connected to 24 VAC or to ground. | |||||||||||||

Common voltage, high side output

|

24 VAC

|

||||||||||||

Common voltage, low side output

|

0 VAC (ground)

|

||||||||||||

Minimum pulse width

|

100 ms

|

||||||||||||

Triac output protection

|

MOV and snubber across each triac output

|

||||||||||||

MOV from triac COM to ground

|

|||||||||||||

Terminals

Follow proper installation wiring diagrams and instructions, including these instructions:

All MP-C models have several RET terminals for connection of I/O returns, so a common chassis/signal ground rail is optional and may not be needed.

Individual 24 V power sources to the field must be current limited to maximum 4 A for UL compliant installations, and maximum 6 A in other areas.

For more information on wiring, see Hardware Reference Guide.

Enterprise Server

Enterprise Server

SpaceLogic AS-P

SpaceLogic AS-P

SpaceLogic AS-B

SpaceLogic AS-B

WorkStation

WorkStation

WebStation

WebStation

SpaceLogic MP-V

SpaceLogic MP-V

Puesta en marcha

Puesta en marcha

Project Configuration Tool: versión 2

Project Configuration Tool: versión 2

Automated Engineering Tool

Automated Engineering Tool