Concetto

SmartStruxure Solution

The SmartStruxure Solution for smoke control includes a wide variety of hardware controllers, I/O modules, and a family of StruxureWare Building Operation (SBO) software products. StruxureWare Building Operation refers to the software running in the Smoke Control Servers, Enterprise Servers, Report Servers and Workstations. The SmartStruxure Solution is an integrated system solution for building management that combines environmental control, energy management, energy monitoring/metering, alarm management, security and reporting. The system can be customized for building management applications extending from small office buildings to skyscrapers and office, school, or industrial campus environments.

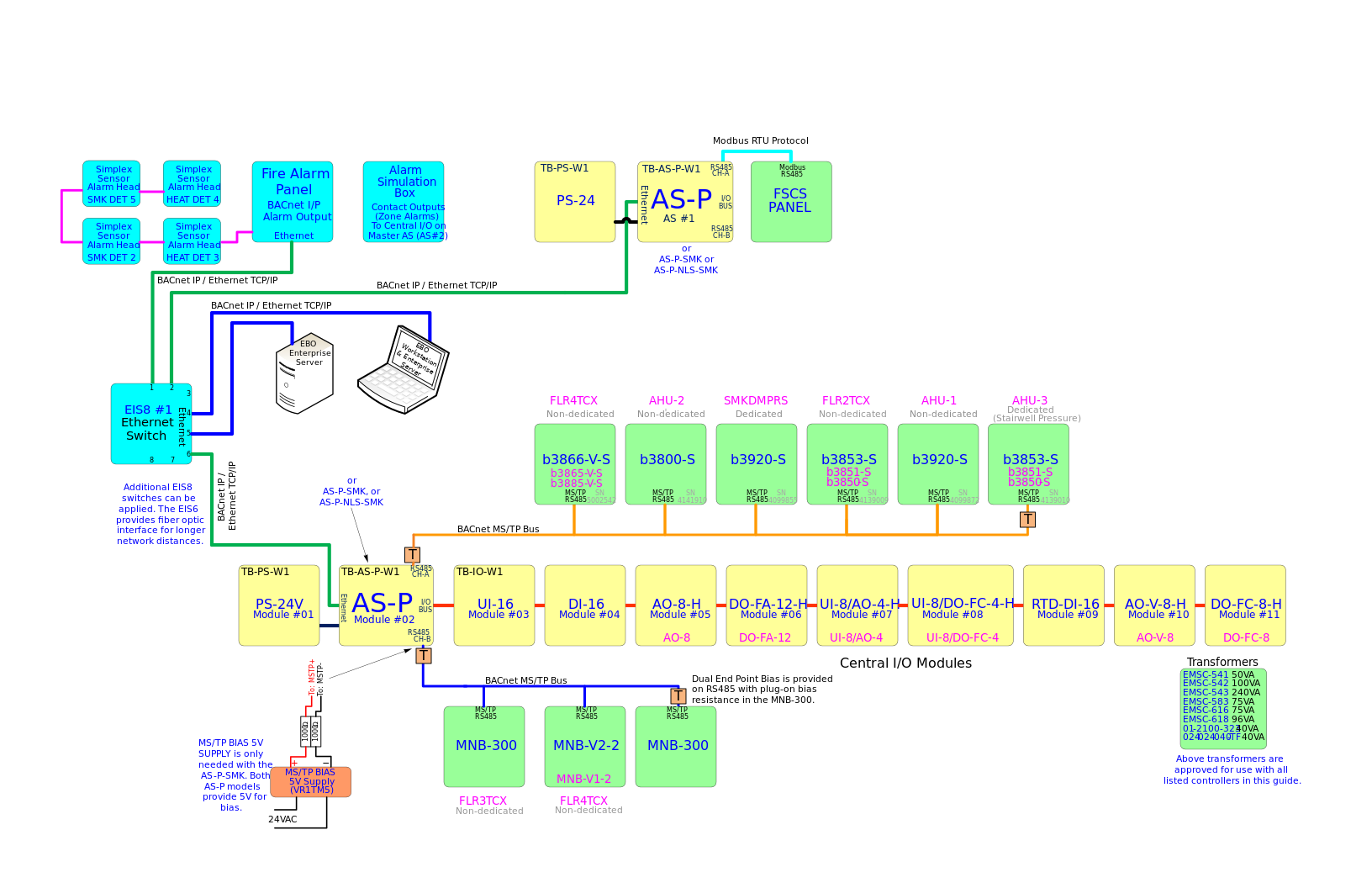

The SmartStruxure Solution smoke control system is constructed with two primary networking tiers. At the top is the TCP/IP network which interconnects all the Smoke Control Servers, Workstation(s) and optional other Enterprise and Report Servers. The BACnet/IP interface to the Fire Alarm Panel (FAP) also operates at the top tier if contact interface to the FAP is not used. The SmartStruxure Solution provides a second tier of communications networks that connect below the Automation Servers or AS-Ps. Up to two RS-485 MS/TP token passing BACnet networks are supported from each Automation Server (Channel-A and Channel-B) or AS-P. Each of the two BACnet network ports support up to 127 MS/TP Field Controllers.

Either of the two RS-485 channels (A or B) on the Smoke Control Servers can be configured for the BACnet MS/TP or Modbus protocol. In a smoke control system, one Smoke Control Server will be assigned to manage the FSCS and one of the RS-485 ports on that Smoke Control Server will be configured for the Modbus protocol to communicate with the FSCS panel.

The following figure presents a simple diagram of the two tier architecture.

The FAP resides on the TCP/IP network and sends alarm information via BACnet/IP to the Smoke Control Server acting as FAP manager (AS-SMK 1 or AS-P-SMK in the figure). The same Automation Server or AS-P also manages the FSCS panel through the Modbus channel. The BACnet/IP connection is supervised from the Smoke Control Server (AS-SMK 1 or AS-P-SMK 1). The Modbus connection is supervised from the FSCS. The two other Automation Servers show the second MS/TP network tier of the system with two BACnet MS/TP buses extending down from AS-SMK 2 (AS-P-SMK 2) and AS-SMK 3 (AS-P-SMK 3). These buses connect to the family of field controllers (b3 and MNB Series) listed in this guide. Per maggior informazioni, consulta MS/TP BACnet Controllers .

The StruxureWare Building Operation software is an open architecture platform operating in the Windows PC environment. It provides a friendly, comprehensive, and customizable set of tools that control and monitor the facility management system through TCP/IP Ethernet and MS/TP networks. The software includes graphics editing for creating customized graphical displays to provide easily interpreted presentations of the information monitored in the facility and accommodate central management and control of the equipment in the facility.

The smoke control system does not depend on these resources to operate. However, it can use them to assist in diagnosing faults reported on the FSCS panel. Per maggior informazioni, consulta FSCS Basics .

While the term SmartStruxure Solution refers to the whole system of hardware and software products, it is worth noting that the Workstation, Enterprise Server, Report Server or WebStation, which may exist on the TCP/IP network, do not participate in the execution of smoke control applications. They also do not transport smoke control communications.

The WorkStation and servers are an integral part of the overall HVAC facility management system and are used to monitor and manage the systems operation including the smoke control applications. After engineering and programming of the smoke control applications within the Smoke Control Servers and field controllers, the SmartStruxure Solution provides password restricted access to the Automation Servers and controllers responsible for smoke control applications.

With Ethernet networks, you cannot achieve the interconnection between the Automations Servers, AS-Ps, FAP and Workstations without additional Ethernet communications equipment. In a smoke control system, the communications required to execute the applications can only pass through equipment included within the UL 864 system listing. To support the TCP/IP network with smoke control systems, the EIS series Ethernet switch products discussed in this guide are approved to interconnect the smoke control TCP/IP products. Per maggior informazioni, consulta Network Accessories .

The following diagram presents a collection of these system elements:

EIS Series Ethernet Switch

Fiber optic models allow operation through extended distances with EMI immunity. The 8 port copper only versions can be used with smaller networks

Automation Server 1 (AS-SMK 1), or AS-P 1 (AS-P-SMK 1) manages and supervises the BACnet/IP connection to the Fire Alarm Panel

Automation Server 1 (AS-SMK 1), or AS-P 1 (AS-P-SMK 1) manages the Modbus connection to the FSCS panel

Automation Server 2 (AS-SMK 2), or AS-P 2 (AS-P-SMK 2) manages two MS/TP channels of b3 field controllers and provides a collection of I/O modules. The 10 fully configured models are listed. All of the models ending with H are available without the H providing the same I/O without the manual override Hand-Off-Auto control on the front.

Automation Server 3 (AS-SMK 3), or AS-P 3 (AS-P-SMK 3) manages two MS/TP channels of MNB and b3 field controllers

Field Controllers – Lists all models approved for the SmartStruxure Solution smoke control application

TCP/IP Network Communications Bus

The TCP/IP network provides the main communication bus throughout a facility. The EIS Ethernet switches are installed around the facility as needed to achieve the distributed port connections for the Automation Servers, or AS-Ps and other TCP/IP components. The network connections used for the smoke control application cannot make use of any other communications devices other than the UUKL recognized EIS Series products listed in this guide.

Category 5 twisted pair cables with RJ-45 connectors should be used for connecting to the Ethernet 10/100 port on the Automation Server or AS-P module. The recommended maximum cable length is 100 meters (330 feet).

All of the ports on the EIS series switches provide isolation from the other ports. A fault on one port will not affect the other ports. The spare 10/100BASE-T ports on the EIS series switches (fiber and copper models) can be used to connect with non-UUKL devices such as Workstations, servers and 3rd party products used within the building automation system.

The BACnet MS/TP bus serving the controllers performing smoke control must not be connected directly with any non-UUKL listed products. When non-UUKL products need to be connected with the MS/TP network for general purpose HVAC comfort control application, one of the following two options can be used:

Connect the non-UUKL product to a separate/isolated MS/TP channel on a Smoke Control Server. For example, the B channel port on a Smoke Control Server could be used to connect non-UUKL products while the A channel is used with the b3 and MNB series products performing smoke control applications.

Connect a b-Link Repeater to any MS/TP channels from the Smoke Control Servers and connect the non-UUKL products on one of the separate ports on the b-Link. That port used to service non-UUKL product must not be used for connecting to any controller participating in the smoke control application. Additionally, when there is a tiered structure with additional b-Link Repeater(s) connected downstream on segment(s) from the initial b-Link Repeater, the segment(s) connecting between b-Link Repeaters must not be connected to any non-UUKL products.

In the following figure, Automation Server (AS-SMK 1), or AS-P (AS-P-SMK 1) shows an example of using the two ports to isolate non-UUKL products, while Automation Server (AS-SMK 2), or AS-P (AS-P-SMK 2) shows the application of a b-Link Repeater to segment and isolate an MS/TP bus. The b-Link provided bus segments can be used for UUKL products or non-UUKL products, but both must not be mixed on the same copper segment.

The MS/TP bus operates at serial data transmission rates of 9600, 19200, 38400, or 76800 bps. Most system installations are installed using 76,800bps. In some installations, however, it may be necessary to lower the speed to 38,400 bps due to the effect of cable characteristics, cable length or node count.

For smoke control applications, it is recommended that the MS/TP bus be run at 38,400 or 76,800bps. This is to minimize the timing latency incurred by the protocol and the load applied to the network by the communications supervision techniques applied to all smoke control controllers.

The following figure presents an example smoke control system configuration used to develop the application programs and submit for the UL 864 system testing and evaluations. The system is presented here simply as a reference associated with features, requirements, and restrictions that must be observed when configuring a compliant smoke control system.

The controllers and other products comprising the example are all represented with boxes. The product model number is shown in blue text. The magenta text lists the smoke control equipment references in the example smoke control application. A number of application programs based on this sample system configuration are provided elsewhere in the smoke control system design guide. Per maggior informazioni, consulta Basic Application Functions .

Smoke Control Operational Overview

Smoke Control Operational Overview

Basic Application Functions

Basic Application Functions