Concept

Automation Server Installation

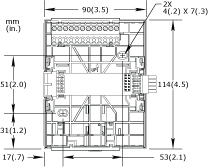

The Automation Server Smoke Control (AS-SMK) uses the model TB-AS-W1 for mounting. To install the Automation Server (AS) on the terminal base, follow these instructions:

Position the Automation Server (AS-SMK) directly to the right of the first (leftmost) PS-24V power supply module on the series I/O bus structure

Slide the TB-AS-W1 terminal base to the left in the DIN rail and mate it together with the TB-PS-W1 power supply terminal base

Connect the various I/O modules to the right side of the TB-AS-W1 base

Automation Servers (AS-SMK) have three communication ports which must be configured for use with the smoke control system. In a smoke control system, the Ethernet port is the primary communications channel connecting through the EIS Series switches (hubs) to the other Automation Servers in the system, the BACnet/IP port of the Fire Alarm Panel (FAP), and the host Workstation(s) for configuration and supplemental system monitoring.

The Automation Server (AS-SMK) also provides two RS-485 communication ports. In a smoke control system, these two ports are used to communicate with the b3/i2 or MNB series controllers or the FSCS panel. Typically, only a single FSCS panel is configured in the system and one of the Automation Servers is assigned the function of managing the FSCS panel and configuring COM-A or COM-B for the Modbus protocol for the FSCS.

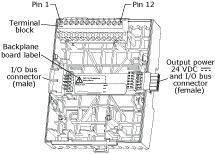

The Automation Server (AS-SMK) includes 12 terminals (#1 to #12) along the top of the terminal base. Two separate plug-in terminal blocks are provided along the bottom side of the Automation Server to permit you to easily disconnect and connect the two RS-485 channels (A and B).

Terminals 4 and 5 provide 10 V power, while terminals 6 and 7 provide RS-485 communications to an optional operator panel (OP). The OP does not participate in the operation of the smoke control system.

Terminals 8 and 9 provide RS-485 communications for connecting to a twisted pair network with LON controllers. You use terminal 10 for connecting the cable shield. Finally, terminals 11 and 12 allow the connection of the FTT-10 Free Topology Transceiver LON network. In the EcoStruxure BMS smoke control system, the LON networks and controllers are available only for HVAC comfort controls and must not be applied to any portion of the smoke control system.

All terminations on the Automation Server are associated with serial data communications. All circuits are Power-Limited.

You connect the RS-485 twisted pair bus from the b3 or MNB controllers to the terminals on the three-position and four-position terminal blocks that plug into the receptacles along the bottom of the unit. These terminals are numbered 13 through 19. For the COM-A RS-485 bus, you connect the MS/TP TX/RX+ and TX/RX- signal wires to terminals 13 and 14 respectively. You connect the cable shield to terminal 15. For the second RS-485 bus (COM-B), you connect the MS/TP TX/RX+ and TX/RX- signal wires to terminals 16 and 17 respectively, and the cable shield to terminal 18. Terminal 19 supplies a 3.3V output which you can use for the RS-485 network bias when required.

The direct connected RS-485 bus cable can be up to 4000 feet in length. You must connect the bus in a direct daisy chain fashion (cable running from one node to the next) with no cable stub connections directly to the main bus. You can connect an RS-485 repeater to extend the length or accommodate stub connections.

See the discussion on repeaters. For more information, see MS/TP Network Accessories .

See also the section on cable routing and cable type recommendations. For more information, see RS-485 Field Bus Cable Routing .

The RS-485 port serving the b3 and MNB controllers is configured for the following:

BACnet MS/TP protocols

Data Rate: 9600 to 76,800bps

Format: 8 Data bits, No Parity, 1 Stop bit

The MS/TP communications path is supervised from the Automation Server (AS-SMK). The Automation Server application program must be configured to monitor the integrity of communications to the b3 and MNB controllers and continuously report the status of the network connection to all smoke control system controllers. This status information is continuously collected by the Automation Server (AS-SMK) operating as the FSCS manager and the Automation Server program must indicate a System Comms Fault on the FSCS panel if a loss of communications occurs with any smoke controllers.

The RS-485 ports used to provide MS/TP bus connections to the smoke control system b3 and MNB series controllers must be isolated from connections to other devices that are not part of the UL 864 listing.

You can connect other non-UL 864 MS/TP products in two ways.

1) You can select a separate MS/TP channel/port from an Automation Server (AS-SMK) to handle non-Listed controller products not partipating in the smoke control system. The separate RS-485 channel (not used for smoke control) from the Automation Server provides the isolation from non-listed products. You must not connect MNB and b3 controllers partipating in the smoke control system to the bus serving the non-listed products.

2) You may connect a bLINK repeater on an MS/TP bus serving smoke control applications. You can use a far-side branch port from the repeater to connect non-listed MS/TP BACnet product(s) to the Automation Server (AS-SMK). The Automation Server must not include the non-listed controller in the smoke control applications. The non-listed controller will be part of other building automation and comfort control systems. The repeater requirements are discussed in the sections that follow.

You can configure either of the two COM-A and COM-B ports for the Modbus protocol and use them for communications with the FSCS panel. The Modbus interface uses the same RS-485 interface. For the COM-A RS-485 bus, you connect the Modbus TX/RX+ and TX/RX- signal wires to terminals 13 and 14 respectively. You connect the cable shield to terminal 15.

For the second RS-485 bus (COM-B), the Modbus TX/RX+ and TX/RX- signal wires connect to terminals 16 and 17 respectively, and the cable shield connects to terminal 18. Terminal 19 supplies a 3.3V output which you can use for RS-485 network bias when required.

The RS-485 port serving the FSCS is configured for the following:

Modbus protocol

Mode: Modbus Slave

Data Rate: 9600 to 76,800bps

Format: 8 Data bits, No Parity, 1 Stop bit

The FSCS communications cable is supervised from the FSCS panel. A break in that connection will be indicated on the FSCS panel by the FSCS COMM FAULT visual indicator and the audible horn. For more information, see FSCS Basics .

The Automation Server (AS-SMK) can be configured with both MS/TP on one channel and Modbus on the other channel independently.

When using either the COM-A or COM-B port, connect one of the shield terminals (15 or 18) to the signals or earth ground rail in the enclosure using 16 AWG wire or larger.

The direct connected RS-485 bus cable can be up to 4000 feet in length. There is no repeater approved for use in the smoke control system with the Modbus protocol. Since it is only a one to one connection, and it will typically involve a relatively short connection from the Automation Server (AS-SMK) to the FSCS, a repeater is not needed. The Modbus protocol may be used on other Automation Servers handling applications such as HVAC comfort control and electrical metering.

The RS-485 Modbus port selected for the FSCS management must not be connected to any other Modbus devices. The only Modbus device defined for use in the smoke control system is the FSCS panel.

You can use any of the CAT-5 or CAT-6 Ethernet cables with RJ-45 modular connectors to connect with the Ethernet port located along the bottom of the Automation Server. The standard cable distance limit on the 10/100 BASE-T connection is 100 meters.

This cable connection must be from the Automation Server (AS-SMK) to one of the EIS series UL 864 approved Ethernet Switch/Hub units listed in this guide. For more information, see MS/TP Network Accessories .

UL-864 compliance imposes a special restriction on this Ethernet cable connection to the Automation Server (AS-SMK). The EIS switch must be installed in the same room as the Automation Server (AS-SMK). The Ethernet cable from the Smoke Control Server must not extend outside this room and there is no defined size limit on the room. This restriction is not applicable to the AS-P-SMK or other IP controllers.

The other 10/100 BASE-T ports on the EIS hub can extend for the standard 100 meter length when connecting to other EIS hubs, AS-P servers, IP field controllers, or to the BACnet/IP interface of the Fire Alarm Panel. The fiber optic versions of the EIS hubs are recommended to support extended cable distances and provide robust Ethernet communications with immunity for EMC in the environment.

The two USB host ports on the bottom of the Automation Server (adjacent to the Ethernet port) provide the standard USB 2.0 Type-A port connection. They are used to supply optional memory and/or communications interface options. These options are not used within the EcoStruxure BMS smoke control system application.

The Automation Server (AS-SMK) provides a USB device port on the face of the unit below the RS-485 LEDs. This is a standard USB 2.0 Type-B port connection. This port is used for connection through a USB cable (up to 3 meters in length) to a maintenance/diagnostic PC for commissioning functions such as installation of firmware when the Ethernet connection is not usable. The USB device port is not used within the EcoStruxure BMS smoke control system application.

EcoStruxure BMS Module Installation

EcoStruxure BMS Module Installation

Terminal Base Installation

Terminal Base Installation

Power Rating

Power Rating

Terminal Base Wiring

Terminal Base Wiring

Electronics Module Installation

Electronics Module Installation

PS-24V Power Supply Module

PS-24V Power Supply Module

AS-P Installation

AS-P Installation

RS-485 Field Bus Cable Routing

RS-485 Field Bus Cable Routing

Module and MP Series Controller Status LEDs

Module and MP Series Controller Status LEDs

I/O Module Installation

I/O Module Installation