The MP-C can be installed on a DIN rail or other flat surface inside a cabinet. The device is recommended to be installed in a cabinet, unless local regulations allow an exception.

Installation orientation restrictions

The restrictions on installing the device in various orientations differ between the different MP-C controller models (

For more information, see MP-C Models

.). In this regard, the MP-C models can be divided in the following categories:

MP-C models without “-M” in the product name:

MP-C-15A, MP-C-18A, MP-C-18B, MP-C-24A, and MP-C-36A

MP-C models with “-M” in the product name:

MP-C-24A-M and MP-C-36A-M

|

Notice

|

|

CONTROLLER DAMAGE

Follow the installation orientation restrictions that apply to the specific MP-C controller model.

Failure to follow these instructions can result in equipment damage.

|

MP-C-15A, MP-C-18A, MP-C-18B, MP-C-24A, and MP-C-36A

Under normal operating conditions of 0 to 50 °C (32 to 122 °F), the MP-C controller models MP-C-15A, MP-C-18A, MP-C-18B, MP-C-24A, and MP-C-36A can be installed in the following orientations:

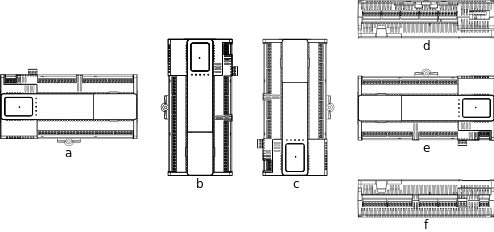

Horizontally (on a DIN rail going from left to right), with the device label text in the upright position reading left to right. See “a” in the following figure.

Vertically (on a DIN rail going from top to bottom), which means that the device is rotated +90 degrees or -90 degrees from the horizontal position. See “b” and “c” in the following figure.

Installing the MP-C rotated 180 degrees from the horizontal position with device label text up and down (“e” in the figure), face down from a ceiling (“d” in the figure), or face up on a horizontal surface (“f” in the figure) is not supported.

action_zoom_plus_stroke

Figure:

Installation orientation restrictions for the MP-C models MP-C-15A, -18A (example), -18B, -24A, and -36A operated in normal conditions, 0 to 50 °C (32 to 122 °F)

When the MP-C is used for rooftop applications, -40 to +60 °C (-40 to +140 °F), the device should be installed horizontally, with the device label text in the upright position reading left to right. See “a” in the following figure. Any other installation orientation (“b”, “c”, “d”, “e”, and “f” in the figure) may exceed the controller's thermal specifications, which can damage the controller.

action_zoom_plus_stroke

Figure:

Installation orientation restrictions for the MP-C models MP-C-15A, -18A (example), -18B, -24A, and -36A operated at -40 to +60 °C (-40 to +140 °F)

MP-C-24A-M and MP-C-36A-M

Under normal operating conditions of 0 to 50 °C (32 to 122 °F), the MP-C controller models MP-C-24A-M and MP-C-36A-M can be installed in the following orientations:

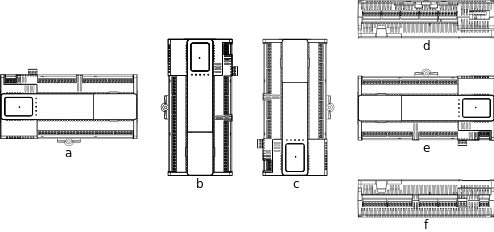

Horizontally (on a DIN rail going from left to right), with the device label text in the upright position reading left to right. See “a” in the following figure.

Vertically (on a DIN rail going from top to bottom), which means that the device is rotated +90 degrees or -90 degrees from the horizontal position. See “b” and “c” in the following figure.

Face down from a ceiling. See “d” in the following figure.

Up and down, which means that the device is rotated 180 degrees from the horizontal position and with the device label text up and down. See “e” in the following figure.

Face up on a horizontal surface. See “f” in the following figure.

action_zoom_plus_stroke

Figure:

Installation orientations for the MP-C models MP-C-24A-M and MP-C-36A-M (example) operated in normal conditions, 0 to 50 °C (32 to 122 °F)

Installation on a DIN rail

A DIN rail is a common and convenient technique for installing the MP-C along with other associated control and monitoring devices. The most efficient ventilation is achieved with the wall-mounted DIN rail oriented horizontally and with adequate space provided between the MP-C rail and adjacent rails or other devices.

The MP-C is typically installed horizontally (on a DIN rail going from left to right), with the device label text in the upright position reading left to right.

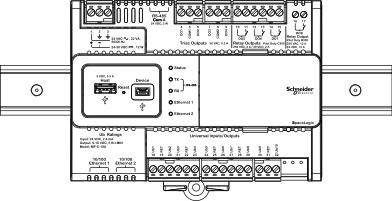

action_zoom_plus_stroke

Figure:

Example of an MP-C controller installed on a horizontal DIN rail

DIN rail end clip

To help prevent the device from sliding down or sideways on the DIN rail, install an end clip for DIN 35 (part number SXWDINEND10001) tightly against the bottom or rightmost device on the rail. The end clip is easily removed if you bend the snap lock open with a screwdriver.

|

Notice

|

|

EQUIPMENT DAMAGE

Use an end clip (part number SXWDINEND10001) when you install the device on a vertical DIN rail.

Failure to follow these instructions can result in equipment damage.

|

action_zoom_plus_stroke

Figure:

End clip for DIN 35 fixed across the DIN rail

Installation in a cabinet

All MP-C controller models are recommended to be installed in a cabinet, unless local regulations allow an exception.

Important:

The device should be installed within an enclosure such as a control cabinet for isolation to exposed live parts.

The MP-C controller can be installed in a standard DIN enclosure/cabinet.

action_zoom_plus_stroke

Figure:

MP-C controllers installed on horizontal DIN rails in a cabinet

When installing MP-C controllers in a cabinet, it is recommended to provide ample space between the DIN rails and controllers for sufficient ventilation.

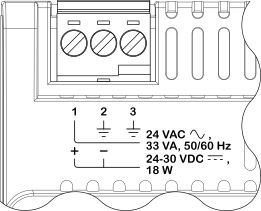

Screw terminals

Most of the MP-C controller models have removable screw terminal blocks for the power input and onboard I/O. The screw terminal blocks are easy to install and remove from the device. You can replace the controller in seconds because no terminal wiring is affected. The terminal blocks are installed on the device at delivery. Spare terminal blocks can be ordered separately using the part number SXWMPCCON10001.

For high-power relay outputs, a two-position fixed terminal block is used. The high-power relay output is only available on the MP-C-15A and MP-C-18A models.

For more information, see MP-C Onboard I/O

.

The MP-C controller models with “-M” in the product name, MP-C-24A-M and MP-C-36A-M, have fixed screw terminals for the power input and onboard I/O and a removable screw terminal block for connection to the BACnet MS/TP (RS-485) network.

MP-C Display

All MP-C controller models, except MP-C-24A-M and MP-C-36A-M, can be equipped with MP-C Display (part number SXWMPCDSP10001), which is an add-on module that enables manual override control of analog and digital outputs. The module consists of an LCD display and keys. The module is designed for permanent installation.

|

Notice

|

|

CONTROLLER DEVICE DAMAGE

Do not try to remove the MP-C Display module.

Failure to follow these instructions can result in equipment damage.

|

Do not try to remove the MP-C Display module as it may damage the enclosure and the module. Once installed, the MP-C Display module cannot be removed.

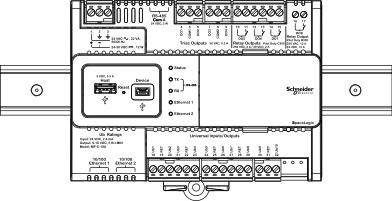

action_zoom_plus_stroke

Figure:

MP-C Display installed on MP-C

MP-C Device Installation

MP-C Device Installation

MP-C Built-in Power Supply

MP-C Built-in Power Supply

Grounding and Power for Systems with MP Controllers

Grounding and Power for Systems with MP Controllers

MP-C Screw Terminals

MP-C Screw Terminals

MP-C-15A Screw Terminals

MP-C-15A Screw Terminals

MP-C-18A Screw Terminals

MP-C-18A Screw Terminals

MP-C-18B Screw Terminals

MP-C-18B Screw Terminals

MP-C-24A Screw Terminals

MP-C-24A Screw Terminals

MP-C-36A Screw Terminals

MP-C-36A Screw Terminals

MP-C-24A-M Screw Terminals

MP-C-24A-M Screw Terminals

MP-C-36A-M Screw Terminals

MP-C-36A-M Screw Terminals

MP-C Controller LEDs

MP-C Controller LEDs

Status LEDs

Status LEDs