Specifications

RP-C-EXT-BL-SMI-4-HV-PD

Introduction

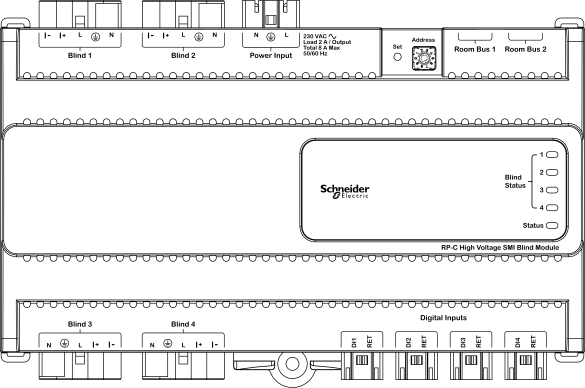

The RP-C-EXT-BL-SMI-4-HV-PD SMI blind module connects to the RP-C room controllers and provides I/O expansion for control of AC mains-supplied motors (drives) with SMI (Standard Motor Interface for AC applications).

The SMI blind module is an SMI certified and registered actuator (controller) that complies to SMI version 3.0. SMI 3.0 offers simplified maintenance, new functions, improved robustness, and high compatibility. The module can be used with products of SMI version 2.0 because the interface is backward compatible.

The SMI high-voltage blind module enables control and power supply (230 VAC) of motorized venetian blinds, roller shutters, awnings, and other shade products (typically for exterior use).

The SMI blind module is part of the RP Series expansion modules for connected room solution and can be combined with other modules from this product range.

Features

The SMI high-voltage blind module has the following features:

Power and communications through the room bus

One SMI channel, which is split into four outputs, for SMI control of 230 VAC powered blinds (opening, closing, positioning)

Four digital inputs for connection of blind switches and window contacts. The digital inputs are SELV (Safety Extra-Low Voltage).

Wieland connectors for quick and easy installation

Engage mobile application for room comfort settings

Status LED for the device

One status LED for each blind output

Rotary switch for address configuration

The SMI interface has the following features:

Up to 16 blind motors or drives can be controlled electrically in parallel (provided the load limits are not exceeded)

High-precision intermediate positioning

Motor feedback with diagnostic information

The RP-C room bus allows RP Series expansion modules and multi-sensors to be connected to the controller for motion detection, luminosity measurements, communication with remote control (RP-C-RC-BLE), and control of electric lights and window blinds.

The RP-C room bus supports up to six connected RP Series expansion modules and multi-sensors with the following restrictions:

Maximum of two DALI light modules

Maximum of two SMI blind modules

Maximum of four multi-sensors

Maximum total length of the room bus is 72 m (236 ft).

The Engage mobile application enables control of room temperature, fan speed, lights, and blinds/shades directly from a smartphone. A user can manage these settings when the application is connected to the RP-C controller.

The Engage mobile application is free and available for download from Google Play and Apple App Store.

For more information, see the Engage Specification Sheet.

|

Product |

Part number |

|

RP-C-EXT-BL-SMI-4-HV-PD

|

SXWRESMI4HVPD10001

|

|

DIN-RAIL-CLIP, DIN-rail end clip

package of 25 pieces

|

SXWDINEND10001

|

Specifications

| Electrical | |

Nominal voltage

|

230 VAC

|

Operating voltage range

|

+/-10 %

|

Frequency

|

50/60 Hz

|

Maximum current consumption

|

8 A

|

Room bus power consumption

|

0.3 W (24 VDC)

|

Protection

|

Maximum 16 A external fuse (circuit breaker) is needed

|

Overvoltage category

|

III

|

| Environment | |

Ambient temperature, operating

|

0 to 50 °C (32 to 122 °F)

|

Ambient temperature, storage

|

-20 to +70 °C (-4 to +158 °F)

|

Humidity

|

20 to 90 % RH non-condensing

|

Pollution degree

|

2

|

| Material | |

Plastic flame rating

|

UL94 V-0

|

Ingress protection rating

|

IP 20

|

| Mechanical | |

Dimensions

|

198 W x 110 H x 64 D mm (7.8 W x 4.3 H x 2.5 D in.)

|

|

|

Weight

|

0.405 kg (0.893 lb)

|

Installation

|

DIN rail or flat surface

|

Connectors

|

Power input: 1 x 3-pin Wieland GST15i3 connector

|

Blind outputs: 4 x 5-pin Wieland GST15i5 connector

|

|

Digital inputs: 4 x 2-pin Wieland GST15i2 connector

|

|

| Software compatibility | |

EcoStruxure Building Operation software

|

version 3.2 and later

|

| Agency compliances | |

Emission

|

RCM; EN 61000-6-3; EN 50491-5-2; FCC Part 15, Sub-part B, Class B

|

Immunity

|

EN 61000-6-2; EN 50491-5-3

|

Safety standards

|

EN 60730-1; EN 60730-2-11; EN 50491-3

|

| Communication ports | |

Room bus

|

RS-485

|

Dual RJ45 ports for daisy-chain configurations

|

|

Use a Cat 5 (or higher) cable

|

|

Maximum total length of the room bus: 72 m (236 ft)

|

|

Room bus protection

|

Transient voltage suppressors on communication and power signals

|

| Hardware | |

CPU type

|

ARM Cortex-M4 single-core

|

Frequency

|

80 MHz

|

SRAM (embedded)

|

320 KB

|

Flash memory (embedded)

|

512 KB

|

NOR flash memory

|

16 MB

|

Status indicator

|

LED (green and red) that shows the status of the device

|

Blind status indicator

|

One status LED (green) for each output

|

Address switch

|

Rotary switch 0 to 9

|

Set button

|

Push-button switch

|

| Blind outputs | |

| SMI motor control outputs for 230 VAC powered blind motors. | |

Outputs

|

4, Blind 1 to Blind 4

|

Output terminals

|

N, PE, L, I+, and I-

|

SMI version

|

3.0

|

Number of SMI channels

|

1

|

Maximum total number of blind motors (drives)

|

16

|

Power distribution

|

230 VAC (same voltage as power supply)

|

Maximum 2 A load per output

|

|

Maximum 8 A total load for the 4 outputs

|

|

| Digital inputs | |

Inputs

|

4, DI1 to DI4

|

Range

|

Dry contact, 0 to 5.0 VDC, 2.2 mA, SELV (Safety Extra-Low Voltage)

|

Connections

Follow proper installation wiring diagrams and instructions. For more information on wiring, see Hardware Reference Guide.

|

Use |

Part number |

Reference |

Connector type |

Suitable for cable diameters mm (inches) |

Marking |

Color of coding /housing |

Minimum order quantity |

|

Power supply input |

SXWRPCCONWWPOW |

91.931.4053.1 |

Female |

5.6–11 (0.22–0.43) |

L, PE, N |

Black /Black |

100 |

|

Blind outputs |

SXWRPCCONWBLSMI |

91.952.4053.1 |

Male |

8.5–12.5 (0.34–0.49) |

N, PE, 1, 2, 3 1: L 2: I+ 3: I- |

Black /Black |

50 |

|

Digital inputs |

SXWRPCCONWDI |

91.921.2353.0 |

Female |

3.4–5.5 (0.14–0.21) |

1, 2 1: DI1..4 2: RET |

Light blue /White |

100 |

The external connectors need to be ordered separately. The connectors can be ordered in quantities of 50 or 100 from Schneider Electric using the above part numbers. The connectors can also be ordered directly from Wieland using the above reference numbers. For more information, see the Wieland Electric web site.

Compatibility with the type and characteristics of the blind motors should be verified at an early stage in your project. In case of uncertainty, additional testing may be required.

RP-C

RP-C

RP-C-EXT-MS-BLE

RP-C-EXT-MS-BLE

RP-C-EXT-DALI-M-PD

RP-C-EXT-DALI-M-PD

RP-C-EXT-0-10V-4-PD

RP-C-EXT-0-10V-4-PD

RP-C-EXT-BL-2-LV-PD

RP-C-EXT-BL-2-LV-PD

RP-C-EXT-BL-4-HV-PD

RP-C-EXT-BL-4-HV-PD

RP-C-EXT-BL-SMI-2-LV-PD

RP-C-EXT-BL-SMI-2-LV-PD

RP-C-EXT-DALI

RP-C-EXT-DALI

RP-C-EXT-0-10V-4

RP-C-EXT-0-10V-4

RP-C-EXT-REL-4

RP-C-EXT-REL-4

Commission

Commission

Engage

Engage