Log on to rate and give feedback

1

2

3

4

5

Log on to rate

0

How to

Products:

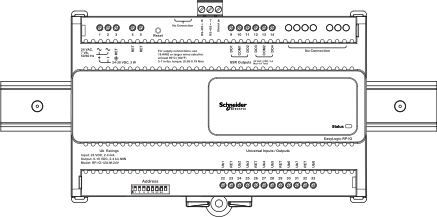

RP-IO

Functionalities:

Hardware

Product version:

2023, 2024

3/30/2023

Powering Up an RP-IO Module

You perform the following steps to power up an RP-IO module.

To power up an RP-IO module

Check that all wiring is correct.

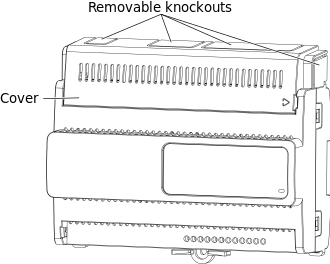

Ensure that appropriate cable strain relief is provided, especially for wires that carry 30 VAC or 42.4 VDC or above.

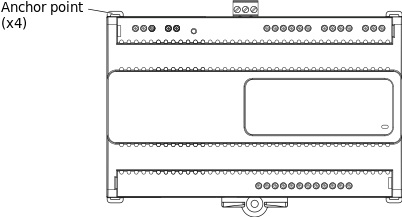

You can use the anchor points on the I/O module enclosure and cable ties to fasten and fix the cables.

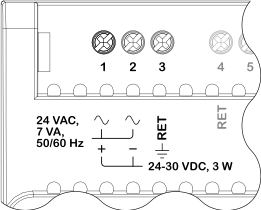

Ensure that the 24 VAC at 50/60 Hz or 24-30 VDC power is supplied to terminals 1 and 2.

action_zoom_plus_stroke

Ensure that the ground cable is connected to terminal number 3.

After powering up, check that the Status LED changes to a constant green light after about a minute.

For more information, see RP-IO Module LED .

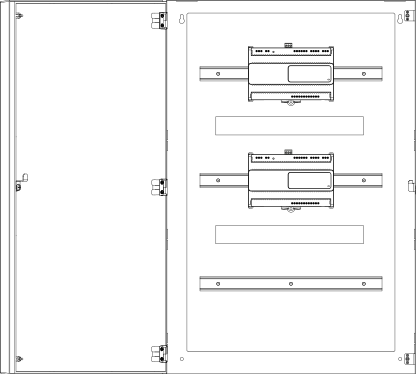

RP-IO Module Device Installation

RP-IO Module Device Installation

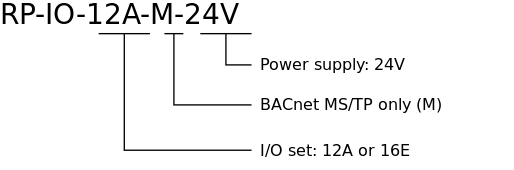

RP-IO Models

RP-IO Models

RP-IO Screw Terminals

RP-IO Screw Terminals

RP-IO-12A-M-24V Screw Terminals

RP-IO-12A-M-24V Screw Terminals

RP-IO-16E-M-24V Screw Terminals

RP-IO-16E-M-24V Screw Terminals

RP-IO Module LED

RP-IO Module LED

Status LEDs

Status LEDs