The SpaceLogic devices with the two-piece design are designed for installation on DIN rails in a cabinet.

Consider a simple example:

action_zoom_plus_stroke

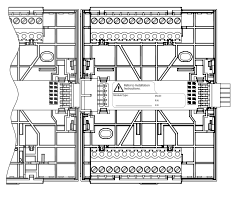

Figura:

SpaceLogic devices: a power supply, an automation server, and two Central IO modules

Two-piece design

Each device consists of two parts:

Terminal base

Electronics module

action_zoom_plus_stroke

Figura:

A hardware device: the electronics module and the terminal base

A separate terminal base means the terminal base can be installed and wired before the electronics module with the application program and data is supplied.

The electronics module is easily plugged in to the terminal base and firmly locked by pushing the handles in place.

Replacing an electronics module is done in seconds because no terminal wiring is affected.

Installation orientation restrictions

|

Avviso

|

|

EQUIPMENT DAMAGE

Follow the installation orientation restrictions that apply to the device.

Failure to follow these instructions can result in equipment damage.

|

The terminal base must be installed horizontally with the backplane board device label text in the upright position reading left to right. Any other installation orientations may exceed the electronics module's thermal specifications, which can damage the electronics module.

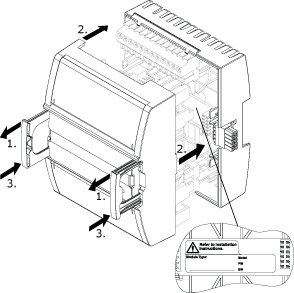

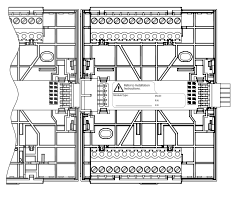

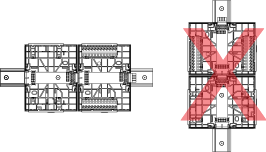

action_zoom_plus_stroke

Figura:

Installation orientation restrictions

Installation on a DIN rail

|

Avviso

|

|

REDUCED LIFE SPAN OF ELECTRONICS MODULE

Always install the terminal base on a horizontal DIN rail to provide sufficient cooling air flow through the electronics module.

Failure to follow these instructions can result in reduced life span of the electronics module.

|

A DIN rail is a common and convenient technique for installing a SpaceLogic device along with other associated control and monitoring devices. The most efficient ventilation is achieved with the wall-mounted DIN rail oriented horizontally and with adequate space provided between the SpaceLogic device rail and adjacent rails or other panel-mounted devices.

The terminal base must be installed on a horizontal DIN rail (going from left to right), with the device label text and the text “UP” (indicated by an arrow) in the upright position reading left to right.

Installing the terminal base on a horizontal DIN rail provides sufficient cooling air flow through the electronics module. Installing the terminal base on a vertical DIN rail can reduce the life span of the electronics module.

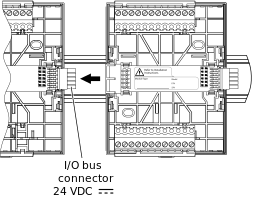

action_zoom_plus_stroke

Figura:

Installing a terminal base on a horizontal DIN rail

The terminal base is recommended to be installed on a DIN rail, but it can also be mounted directly on the wall.

DIN rail end clip

To prevent the modules from sliding sideways on the DIN rail, fix an end clamp for DIN 35 (part number SXWDINEND10001) tightly against the rightmost device on the rail. The end clamp is easily removed if you bend the snap lock open with a screwdriver.

action_zoom_plus_stroke

Figura:

End clamp for DIN 35 fixed across the DIN rail

Installation in a cabinet

Install the terminal bases horizontally in the cabinet with ample space between the DIN rails and devices for sufficient cooling air flow through the electronics modules.

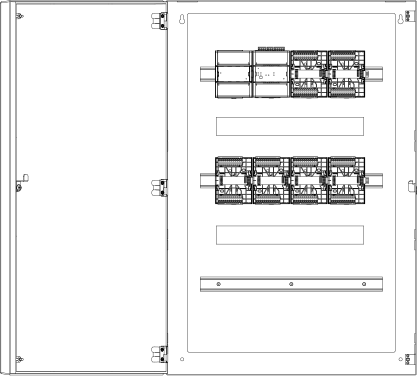

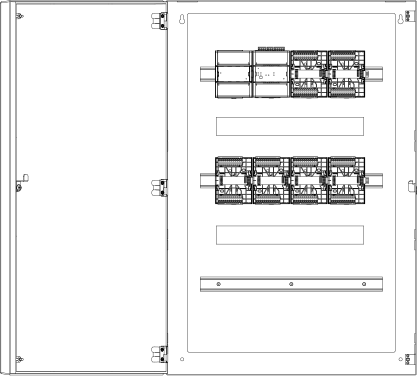

action_zoom_plus_stroke

Figura:

Power supply, automation server, and terminal bases for Central IO modules installed on horizontal DIN rails in a cabinet

Installation of electronics modules on terminal bases

Allarme

Allarme

|

|

HAZARD OF ELECTRIC SHOCK OR EQUIPMENT DAMAGE

Install only the module type that is indicated on the label on the terminal base backplane.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

|

To ensure that the correct electronics module is used with the correct terminal base, you must always check that the warning label on the terminal base backplane indicates which module type is to be connected. Write the intended module type, if it is not already printed, on the label.

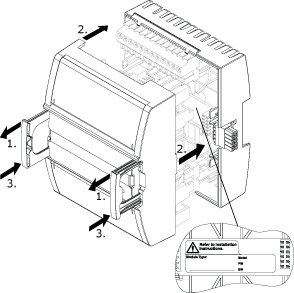

action_zoom_plus_stroke

Figura:

Terminal base with label for intended module type

Install only the module type that is indicated on the label on the terminal base backplane. A mismatch can cause electric shock and damage the electronics module.

If the label does not indicate the intended module type, consult the control panel documentation to determine the intended module type.

The electronics module is easily plugged in to the terminal base and firmly locked by pushing the handles in place.

action_zoom_plus_stroke

Figura:

Installing an electronics module on a terminal base

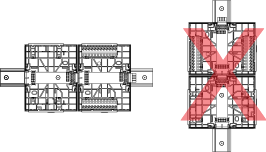

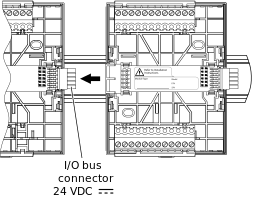

Connection of the next terminal base on the I/O bus

The terminal bases are connected to each other by sliding the terminal bases together using the built-in connectors.

action_zoom_plus_stroke

Figura:

Connecting terminal bases

S-cables

The chain of devices can be split on multiple DIN rails (rows) by using an extension cord called S-cable. Maximum five S-cables are allowed per system. The S-cable connects the last (rightmost) device on one DIN rail with the first (leftmost) device on the next DIN rail.

The complete chain of devices must remain within one cabinet for EMC reasons. When the I/O bus size or quantity of I/O modules exceeds the capacity of a single cabinet, you can extend the I/O bus using an S-cable to a second, adjacent cabinet. Both cabinets must be securely fastened together and electrically connected to function as a single unit. This ensures continuous electromagnetic compatibility (EMC) protection, equivalent to that of a single cabinet. Mechanical bonding involves securely fastening the cabinets together, while electrical bonding ensures a common grounding and shielding system, minimizing electromagnetic interference and maintaining signal integrity.

The following figure shows an example of how you can use an S-cable to connect devices that are installed on separate DIN rails in a cabinet. For sufficient cooling air flow through the devices, the DIN rails and the devices are installed horizontally in the cabinet.

action_zoom_plus_stroke

Figura:

Devices installed on separate, horizontal rails and connected using an S-cable

The S-cable is available with right angle connectors and in 1.5 m (5 ft) and 0.75 m (2 ft 5 in) lengths. You can serially connect up to two S-cables to extend the length.

The following image shows the minimum space required for plugging/unplugging the S-cable from the device but also provides information on the minimum bend radius required to reduce the stress of the cable. The S-cable with straight connectors is a discontinued product, which can no longer be ordered from Schneider Electric.

action_zoom_plus_stroke

Figura:

S-cable connecting devices on separate rails

Device order

The order in which the devices are installed in the chain (I/O bus) is important. The devices should be installed in the following order:

Position 1 (leftmost): Power supply (mandatory)

Position 2: AS-P server (mandatory)

Position 3 to 32: Central IO modules and extra power supplies as needed based on power budget. One power supply can supply power for loads up to 30 W.

Per maggior informazioni, consulta Power Budget

.

Avviso

There is a limit of one automation server per I/O bus.

The rules are summarized in the following illustration.

action_zoom_plus_stroke

Figura:

Order of devices on the I/O bus

Device Installation

Device Installation

Status LEDs

Status LEDs

Electronics Modules

Electronics Modules

Allarme

Allarme