Specifications

SpaceLogic AS-P

Introduction

At the core of an EcoStruxure BMS is an automation server, such as the SpaceLogic™ AS-P server. The AS-P server performs key functionality, such as control logic, trend logging, and alarm supervision, and supports communication and connectivity to the I/O and field buses. The distributed intelligence of the EcoStruxure BMS helps ensure fault tolerance against detected faults and provides a fully featured user interface through WorkStation and WebStation.

Features

The AS-P server is a powerful device that can act as a standalone server and also control Central IO modules and monitor and manage field bus devices. In a small installation, the embedded AS-P server acts as a standalone server, mounted with its Central IO modules in a small footprint. In medium and large installations, functionality is distributed over multiple automation servers that communicate over TCP/IP.

The AS-P server has the following features:

Communications hub

Variety of connectivity options

Zigbee wireless network support

Authentication and permissions through powerful systems

WorkStation/WebStation interface

Native BTL-listed BACnet support

BACnet/SC node, hub, or router

Native LonWorks support

Native Modbus support

Additional building protocol support

Web Services support based open standards

EcoStruxure Web Services support

MQTT IoT protocol support

External log storage option

Reporting

Scalable custom configurations

I/O expansion option

Text and graphics-based programming tools

eMMC memory for data and backup

IT friendly networking based on the TCP/IP suite of communication protocols

TLS support

Patented two-piece design

Auto-addressing

Simple DIN-rail installation

Secure boot

Capable of coordinating traffic from above and below its location, the AS-P server can deliver data directly to you or to other servers throughout the site. The AS-P server can run multiple control programs, manage local I/O, alarms, and users, handle scheduling and logging, and communicate using a variety of protocols. Because of this, most parts of the system function autonomously and continue to run as a whole even if communication is interrupted or individual EcoStruxure BMS servers or devices go offline.

An AS-P server has numerous ports that enable it to communicate with a wide range of protocols, devices, and servers.

An AS-P server has the following ports:

Two 10/100 Ethernet ports

Two RS-485 ports

One LonWorks TP/FT port (not available on AS-P server models with “NL” in the product name)

One built-in I/O bus port

One USB device port

One USB host port

The first Ethernet port is dedicated to the site network. The second Ethernet port is fully configurable. The second port can be configured to extend the site network so that various devices and clients can be connected. Another option is to configure the second port as a separate network, which means that the port can host a private network. This port configuration with dual networks requires hardware version 0.62 or higher. If the second port is not used, it can be disabled.

The USB device port allows you to upgrade and interact with the AS-P server using Device Administrator.

Using a USB Ethernet adapter, you can connect a laptop PC to the USB host port and run Device Administrator, WorkStation, and WebStation to upgrade, configure, and access the AS-P server. The USB host port can also be used to provide power and communications for Wireless Adapter - Advanced.

Through Wireless Adapter - Advanced connected to the host USB port, Zigbee TM wireless connectivity can be enabled for the automation server. The automation server can extend its point count through the Zigbee wireless network and bring flexibility in your applications. The automation server equipped with the adapter is together a Zigbee Certified Product that is compliant with Zigbee 3.0. For more information on the adapter and supported wireless devices, see the Wireless Adapter - Advanced Specification Sheet.

An EcoStruxure BMS provides a powerful permission system that is easy to manage, flexible, and adapts to all kinds of system sizes. The permission system provides a high standard of authentication. Authentication is done against the built-in user account management system or against Windows Active Directory Domains. The built-in account management system allows an administrator to establish password policies that meet stringent cybersecurity guidelines. When Windows Active Directory is used, the administration costs are lower because users do not have to be managed in multiple directories.

Through any client, the user experience is similar regardless of which EcoStruxure BMS server the user is logged on to. The user can log directly on to an AS-P server to engineer, commission, supervise, and monitor the AS-P server as well as its attached Central IO modules and field bus devices. See the WorkStation and WebStation specification sheets for additional information.

One of the cornerstones of the EcoStruxure BMS is support for open standards. The AS-P server can natively communicate with three of the most popular standards for buildings: BACnet (including BACnet/SC), LonWorks, and Modbus.

An AS-P server communicates directly to BACnet/IP and BACnet MS/TP networks. The AS-P servers are BTL-listed as BACnet Building Controllers (B-BC), the most advanced BACnet Device Profile. This capability provides access to an extensive range of BACnet devices from Schneider Electric and other vendors. See the BTL Product Catalog for up-to-date details on BTL listed firmware revisions on BACnet International's home page. An AS-P server can also serve as a BACnet Broadcast Management Device (BBMD) to facilitate BACnet systems that span multiple IP subnets.

The Enterprise Server and automation servers support BACnet/SC applications as a BACnet/SC node, hub, and router. This allows the Enterprise Server and automation servers to be in BACnet/SC networks and support applications that connect BACnet/IP or MS/TP networks with BACnet/SC networks. A major benefit of BACnet/SC is that it allows more secure transport of BACnet traffic and information between BACnet/SC devices over private and public networks without the need for BBMDs, VLANs, and VPNs, because the BACnet/SC protocol uses WebSocket technology and TLS 1.3 encryption. In addition, BACnet/SC uses certificate management to help ensure only those devices authorized to be on a BACnet/SC network can operate on that network.

The AS-P server has a built-in FTT-10 port to communicate to the TP/FT-10 LonWorks network. Integrated LonWorks functionality enables access to LonWorks devices from Schneider Electric and other vendors. LonWorks networks can be commissioned, bound, and configured from the AS-P server using the built-in LonWorks Network Management Tool. No third-party tools are needed. A protocol analyzer with powerful debugging and network quality monitoring features can be achieved using third-party software, without additional hardware needed. To increase ease of use, LNS device plug-ins are supported. This allows for easier engineering and maintenance of LonWorks devices from Schneider Electric and other vendors. There are some limitations on how LNS device plug-ins can be used.

AS-P server models with “NL” in the product name, for example AS-P-NL and AS-P-NLS, do not support LonWorks.

The Enterprise Server and automation servers natively integrate Modbus RS-485 client and server configurations, as well as Modbus TCP client and server. This allows full access to third-party products and the range of Schneider Electric products that communicate on the Modbus protocol, such as power meters, UPS, circuit breakers, and lighting controllers.

Modbus device types are pre-configured Modbus applications for quick and easy Modbus device integration in EcoStruxure Building Operation solutions. For information on the Modbus devices supported using Modbus device types, see the document EcoStruxure Building - Modbus Device Integration - Supported Device Brochure.

The AS-P server also supports integration and communication with Schneider Electric supplied BMS systems and devices that use the Andover Continuum Infinet standard for buildings.

The AS-P server supports the use of Web Services based on open standards, such as SOAP and REST, to consume data into the EcoStruxure BMS. Use incoming third-party data (temperature forecast, energy cost) over the Web to determine site modes, scheduling, and programming.

EcoStruxure Web Services, Schneider Electric’s Web Services standard, is natively supported in the EcoStruxure BMS servers. EcoStruxure Web Services offers extra features between compliant systems whether within Schneider Electric or other authorized systems. These features include system directory browsing, read/write of current values, alarm receipt and acknowledgement, and historical trend log data. EcoStruxure Web Services requires user name and password to log on to the system.

The Enterprise Server and automation servers support MQTT as an option for publishing data to, and receiving updates from, other systems. MQTT is a messaging transport protocol that with its small footprint, light bandwidth utilization, and simplicity, is ideal for M2M and IoT communication. The MQTT capability supports communication with any MQTT broker, for example, Amazon, Microsoft, Google or IBM.

EcoStruxure BMS servers can be configured to automatically store all historical data, trend log data, event log and audit trail data, in an external database. If data needs to be available for longer periods of time, an external log storage can be incorporated into the EcoStruxure BMS without the need for extensive engineering work. The supported databases are TimescaleDB, which is built on PostgreSQL, and Microsoft SQL Server. The data in the external log storage is available natively to the viewers built into the EcoStruxure Building Operation clients and to the built-in reporting functionality.

You can use the powerful Log Processor functionality for custom processing of trend data for viewing in charts, dashboards and for inclusion in reports. The Log Processor enables advanced calculations on one or multiple trend logs and point values.

Examples of advanced calculations:

Energy usage normalization

Virtual submeters and summaries

Calculation of Mean Kinetic Temperature

Unit conversions

Average, maximum, and mini m um over custom periods

The output of the Log Processor can be saved in the database, including the External Log Storage or calculated automatically on demand.

From EcoStruxure Building Operation version 5.0.3 and later, selected trend logs and the event log can be sent to AVEVA PI System directly without the need for intermediate storage or specialized PI System connectors.

The EcoStruxure BMS servers provide built-in functionality for basic reporting that can deliver reports in any text format and XLSX, without any dependencies to other external software. Reports for XLSX can be enriched by using advanced functionality such as formulas, conditional formatting, charts and sparklines.

Reports can be generated on schedule, on an alarm event or other custom conditions, and you can get the output delivered via email or written to file.

The AS-P server and its family of Central IO modules were designed to meet the unique needs of each installation. Depending on the configuration, each AS-P server can control up to 464 I/O points. Because power and communications are delivered along a common bus, multiple modules can be plugged together without tools in a simple one-step process using the built-in connectors.

For applications that require remote I/O resources, the SpaceLogic IP-IO modules provide a versatile mix of I/O points for any application. For more information, see the SpaceLogic IP-IO Specification Sheet.

Unique to the industry, the EcoStruxure BMS servers have both Script and Function Block programming options. This flexibility helps assure that a suitable programming method can be selected for the application.

The automation server has a 4 GB eMMC memory, which is used, for example, for the application, historical data, and backup storage. Users can also manually back up or restore the automation server to a storage location on a PC or network. Through the Enterprise Server, users have the ability to perform scheduled backups of associated automation servers to network storage for even greater levels of protection.

The EcoStruxure BMS servers communicate using the networking standards. This makes installations easy, management simple, and transactions more secure.

IP addressing

TCP communications

DHCP for easy network configuration

DNS for simple lookup of addresses

HTTP/HTTPS for Internet access through firewalls, which enables remote monitoring and control

NTP (Network Time Protocol) for time synchronization throughout the system

SMTP or SMTPS with support for SSL/TLS based authentication, enables sending email messages triggered by schedule or alarm

SNMP enables network supervision and reception of application alarms in designated network management tools

WebSocket Secure (WSS) and TLS 1.3 encryption (BACnet/SC applications)

Communication between clients and the EcoStruxure BMS servers , and between EcoStruxure BMS servers, can be encrypted using Transport Layer Security (TLS ). The servers are delivered with a default self-signed certificate. Commercial Certification Authority (CA) server certificates are supported to lower the risk of malicious information technology attacks. Use of encrypted communication can be enforced for both WorkStation and WebStation access.

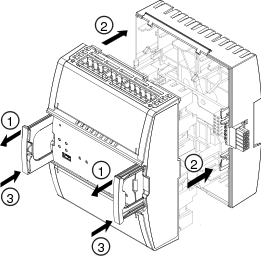

Each module can be separated from its terminal base to allow the site to be wired prior to the installation of the electronics. The patented locking mechanism serves as handles for removing the module from its base. All critical components have a protective cover that permits convection cooling to occur.

The auto-addressing feature helps eliminating the need for setting DIP switches or pressing commission buttons. Each module automatically knows its order in the chain and assigns itself accordingly – significantly reducing engineering and maintenance time.

Fasteners easily snap into a locked position for panel installation. The fastener has a quick-release feature for easy DIN-rail removal.

Secure boot is a security standard to help ensure that a device boots using only software that is trusted by Schneider Electric.

Secure boot is supported by AS-P server models with “S” in the product name, for example AS-P-S and AS-P-NLS.

Specifications

| Electrical | |

DC input supply power

|

10 W

|

DC input supply voltage

|

24 VDC

|

| Environment | |

Ambient temperature, operating

|

0 to 50 °C (32 to 122 °F)

|

Ambient temperature, storage

|

-20 to +70 °C (-4 to +158 °F)

|

Maximum humidity

|

95 % RH non-condensing

|

| Material | |

Plastic flame rating

|

UL94-5VB

|

Enclosure

|

PC/ABS

|

Ingress protection rating

|

IP 20

|

| Mechanical | |

Dimensions including terminal base

|

90 W x 114 H x 64 D mm (3.6 W x 4.5 H x 2.5 D in.)

|

|

|

Weight including terminal base

|

0.321 kg (0.71 lb)

|

Weight excluding terminal base

|

0.245 kg (0.54 lb)

|

| Agency compliances | |

Emission

|

RCM; BS/EN 61000-6-3; BS/EN IEC 63044-5-2; FCC Part 15, Sub-part B, Class B

|

Immunity

|

BS/EN 61000-6-2; BS/EN IEC 63044-5-3

|

Safety standards

|

BS/EN 60730-1; BS/EN 60730-2-11; BS/EN IEC 63044-3; UL 916 C-UL US Listed

|

Product

|

BS/EN IEC 63044-1

|

Smoke control product safety

a

|

UL 864

|

| a) Applies to the Smoke Control (SMK) models. For specifications and information on the restrictions that apply to the SMK models when used in UL 864 smoke control systems, see the EcoStruxure Building Management - Smoke Control System Design Guide, 04-16014-XX-en. | |

| Real-time clock | |

Accuracy in runtime mode

|

NTP server

|

Accuracy in backup mode, at 25 °C (77 °F)

|

+/-52 seconds per month

|

Backup time, at 25 °C (77 °F)

|

10 days

|

| Communication ports | |

Ethernet

|

Dual 10/100BASE-TX (RJ45), IEEE 802.3 compliant

|

USB

|

1 USB 2.0 device port (mini-B)

|

1 USB 2.0 host port (type-A), 5 VDC, 2.5 W

|

|

RS-485

|

Dual 2-wire ports, bias 5.0 VDC

|

LonWorks

a

|

TP/FT-10

|

| a) AS-P server models with “NL” in the product name, for example AS-P-NL and AS-P-NLS, do not support LonWorks. | |

| Communications | |

BACnet

|

BACnet/IP, port configurable, default 47808

|

BACnet/SC, port configurable, no default port

|

|

BACnet profile

|

BACnet Building Controller (B-BC), BACnet Secure Connect Hub (B-SCHUB), AMEV AS-B

|

BACnet certification

|

BTL Certification (BTL Listing

a

, WSPCert)

|

| a) See the BTL Product Catalog for up-to-date details on BTL listed firmware revisions on BACnet International's homepage. | |

Modbus

a

|

Modbus TCP, client and server

|

Modbus RTU and ASCII, RS-485, client and server

|

|

| a) AS-P-S (SXWASPSBX10001) and AS-P-NLS (SXWASPSBX10002) require a separate Modbus license (SXWSWX000MBRTU). | |

MQTT

|

MQTT over TLS, port configurable, default 8883

|

MQTT over TCP, port configurable, default 1883

|

|

MQTT over WebSocket Secure (WSS), port configurable, default 443

|

|

MQTT over WebSocket (WS), port configurable, default 80

|

|

TCP

|

Binary, port fixed, 4444

|

HTTP

|

Non-binary, port configurable, default 80

|

HTTPS

|

Encrypted supporting TLS 1.3, 1.2, 1.1

a

, and 1.0

a

, port configurable default 443

|

| a) Disabled by default. | |

WSS

a

|

Encrypted supporting TLS 1.3, port configurable

|

| a) BACnet/SC applications | |

SMTP

|

Email sending, port configurable, default 25

|

SMTPS

|

Email sending, port configurable, default 587

|

SNMP

|

version 3

|

Network supervision using poll and trap

|

|

Application alarm distribution using trap

|

|

| Terminals | |

| The terminals of the AS-P and AS-P-S models are shown below. | |

|

|

| The terminals of the AS-P-NL and AS-P-NLS models are shown below. | |

|

|

| LNS | |

LNS version

|

OpenLNS

|

Installed on WorkStation PC

|

|

| LonMark | |

Resource files version

|

14.00

|

| CPU | |

Frequency

|

500 MHz

|

Type

|

SPEAr1380, ARM Cortex-A9 dual-core

|

DDR3 SDRAM

|

512 MB

|

eMMC memory

|

4 GB

|

Memory backup

|

Yes, battery-free, no maintenance

|

| Part numbers | |

SpaceLogic AS-P

|

SXWASPXXX10001

|

SpaceLogic AS-P-S

|

SXWASPSBX10001

|

SpaceLogic AS-P-SBA

a

|

SXWASPSBX10A01

|

| a) AS-P-SBA is Buy American Act (BAA) compliant. AS-P-SBA is also included in a BAA compliant bundle that includes the AS-P-SBA server, TB-ASP-W1-BAA terminal base, PS-24V-BAA power supply, and TB-PS-W1-BAA terminal base. AS-P-SBA can be ordered separately using the part number SXWASPSBX10A01. The bundle can be ordered using the part number SXWASPSBXB10A01. AS-P-SBA does not differ from AS-P-S in terms of hardware and functionality. | |

SpaceLogic AS-P-NL

|

SXWASPXXX10002

|

SpaceLogic AS-P-NLS

|

SXWASPSBX10002

|

SpaceLogic AS-P-SMK

a

|

SXWASPXXX1S001

|

| a) Approved for use in UL 864 smoke control systems. The Smoke Control (SMK) models are shipped with a validated UL 864 software version, which can differ from the latest released software. For information on the approved software revisions for the device when used in UL 864 smoke control systems, see the Smoke Control System Approved Software Revisions - EcoStruxure Building Management document, 01-16001-XX-en. | |

SpaceLogic AS-P-NLS-SMK

a

|

SXWASPSBX1S002

|

| a) Approved for use in UL 864 smoke control systems. The Smoke Control (SMK) models are shipped with a validated UL 864 software version, which can differ from the latest released software. For information on the approved software revisions for the device when used in UL 864 smoke control systems, see the Smoke Control System Approved Software Revisions - EcoStruxure Building Management document, 01-16001-XX-en. | |

TB-ASP-W1, Terminal Base for AS-P servers

|

|

(Required for each AS-P server)

|

SXWTBASW110002

|

TB-ASP-W1-BAA, Terminal Base for AS-P servers

a

|

|

(Required for each AS-P server)

|

SXWTBASW110A02

|

| a) TB-ASP-W1-BAA is included in a Buy American Act (BAA) compliant bundle that includes the AS-P-SBA server, TB-ASP-W1-BAA terminal base, PS-24V-BAA power supply, and TB-PS-W1-BAA terminal base. TB-ASP-W1-BAA can only be ordered using the part number for the AS-P-SBA bundle (SXWASPSBXB10A01). TB-ASP-W1-BAA does not differ from TB-ASP-W1 in terms of hardware and functionality. | |

| Accessory part numbers | |

AS-P connector kit

|

SXWASPCON10001

|

SpaceLogic Wireless Adapter - Advanced

|

SXWZBAUSB10001

|

| Software bundles | |

| AS-P-S and AS-P-NLS | |

| In the following description, a Connected Product is a communicating device directly connected to a BACnet, Modbus, Infinet, LonWorks, or Zigbee network driven by the AS-P server. A SpaceLogic Central IO module, a device connected to an RP or MP controller, a non-communicating sensor, valve, or actuator, or a LonWorks local node is not a Connected Product. | |

AS-P – Standalone SW

|

|

Support for 10 Connected Products and 6 Central IO modules.

|

SXWSWXBU0000SA

|

AS-P – Standard SW

|

|

Support for 25 Connected Products, 30 Central IO modules, and Enterprise Server communication.

|

SXWSWXBU0000SD

|

AS-P – Enhanced SW

|

|

Support for 100 Connected Products, 30 Central IO modules, and Enterprise Server communication.

|

SXWSWXBU0000EN

|

AS-P – Full SW

|

|

Support for 300 Connected Products, 30 Central IO modules, and Enterprise Server communication.

|

SXWSWXBU0000FU

|

Modbus – SpaceLogic AS-P Server

|

|

Modbus software add-on, for AS-P-S and AS-P-NLS bundles.

|

SXWSWX000MBRTU

|

AS-P Bundle Upgrade – Standalone to Standard

|

|

Upgrades from 10 to 25 Connected Products, from 6 to 30 Central IO modules, and adds Enterprise Server communication.

|

SXWSWXUP00SASD

|

AS-P Bundle Upgrade – Standalone to Enhanced

|

|

Upgrades from 10 to 100 Connected Products, from 6 to 30 Central IO modules, and adds Enterprise Server communication.

|

SXWSWXUP00SAEN

|

AS-P Bundle Upgrade – Standalone to Full

|

|

Upgrades from 10 to 300 Connected Products, from 6 to 30 Central IO modules, and adds Enterprise Server communication.

|

SXWSWXUP00SAFU

|

AS-P Bundle Upgrade – Standard to Enhanced

|

|

Upgrades from 25 to 100 Connected Products.

|

SXWSWXUP00SDEN

|

AS-P Bundle Upgrade – Standard to Full

|

|

Upgrades from 25 to 300 Connected Products.

|

SXWSWXUP00SDFU

|

AS-P Bundle Upgrade – Enhanced to Full

|

|

Upgrades from 100 to 300 Connected Products.

|

SXWSWXUP00ENFU

|

| AS-P and AS-P-NL | |

AS-P Upgrade Non-Secure Boot – Standalone

|

|

Standalone AS-P upgrade. Upgrades AS-P or AS-P-NL from EcoStruxure Building Operation software version 3.x to 4.0 or later. Not compatible with secure boot hardware.

|

SXWSWASPUP30SA

|

AS-P Upgrade Non-Secure Boot – Standard

|

|

Standard AS-P upgrade. Upgrades AS-P or AS-P-NL from EcoStruxure Building Operation software version 3.x to 4.0 or later. Not compatible with secure boot hardware.

|

SXWSWASPUP30SD

|

AS-P Upgrade Non-Secure Boot – Enhanced

|

|

Enhanced AS-P upgrade. Upgrades AS-P or AS-P-NL from EcoStruxure Building Operation software version 3.x to 4.0 or later. Not compatible with secure boot hardware.

|

SXWSWASPUP30EN

|

AS-P Upgrade Non-Secure Boot – Full

|

|

Full AS-P upgrade. Upgrades AS-P or AS-P-NL from EcoStruxure Building Operation software version 3.x to 4.0 or later. Not compatible with secure boot hardware.

|

SXWSWASPUP30FU

|

AS-P Upgrade Non-Secure Boot – Full – Bulk Pack 125

|

|

Bulk pack for upgrading AS-P or AS-P-NL from EcoStruxure Building Operation software version 3.x to 4.0 or later. Contains 125 pieces of SXWSWASPUP30FU.

|

SXWSWASPUP30BP

|

| Add-on options | |

| AS-P, AS-P-S, AS-P-NL, and AS-P-NLS | |

SW-EWS-1, EcoStruxure Web Services (run-time) option

|

|

Consume only for one automation server

|

SXWSWEWSXX0001

|

SW-EWS-2, EcoStruxure Web Services (run-time) option

|

|

Serve & Consume for one automation server

|

SXWSWEWSXX0002

|

SW-EWS-3, EcoStruxure Web Services (run-time) option

|

|

Serve & Consume, plus Historical trend log data for one automation server

|

SXWSWEWSXX0003

|

SW-GWS-1, Web Services (Generic Consume) option

|

|

For one automation server

|

SXWSWGWSXX0001

|

SW-SNMP-1, Alarm notifications via SNMP option

|

|

For one automation server

|

SXWSWSNMPX0001

|

EcoStruxure Building Operation SmartDriver option

|

|

For one AS-P server

|

SXWSWSDRVX0001

|

Building Operation Personal Dashboards option, 1 per server required for users logging on to that server to have Personal Dashboard capabilities

|

|

For one automation server

|

SXWSWDASHX0001

|

SW-ASDBTS-1, TimescaleDB connection option

|

|

For one automation server (not required if the parent Enterprise Server has a license)

|

SXWSWASDBXS001

|

EcoStruxure Building Operation, Microsoft SQL Server connection option

|

|

For one automation server (not required if the parent Enterprise Server has a license)

|

SXWSWASDBMS001

|

EcoStruxure Building Operation, AVEVA PI System connection option

|

|

For one automation server (not required if the parent Enterprise Server has a license)

|

SXWSWASDBPI001

|

SW-ASMQTT-1, MQTT

option

|

|

For one automation server (not required if the parent Enterprise Server has a license)

|

SXWSWMQTTXRW01

|

SAML Authentication

option

|

|

F

or

one

SpaceLogic automation server

|

SXWSWASSAML001

|

| Software requirements | |

External log storage PostgreSQL option

|

Supported versions of PostgreSQL (

www.postgresql.org

) with matching version of TimescaleDB extension (

www.timescale.com

).

|

Note: To use compression for trend data, TimescaleDB 2.11 or later is required.

|

|

| Quality assurance testing has been performed by Schneider Electric with TimescaleDB and PostgreSQL installed natively in Windows 10, Windows Server 2012, 2016, and 2019. Other deployment scenarios have not been tested by Schneider Electric. | |

External log storage Microsoft SQL option

|

Microsoft SQL Server versions under full support by Microsoft (

www.microsoft.com

).

|

| The following Microsoft SQL Server editions are supported: Enterprise, Standard, and Express. | |

External log storage AVEVA PI System option

|

PI Web API 2021 SP3 and database compatible with that version

|

| Quality assurance testing has been performed by Schneider Electric with PI Web API 2021 SP3, and database compatible with that version, installed on Windows Server 2019. Other deployment scenarios have not been tested by Schneider Electric. | |

Enterprise Server

Enterprise Server

SpaceLogic PS-24V

SpaceLogic PS-24V

WorkStation

WorkStation