Specifications

EasyLogic RP-V

Introduction

EasyLogic™ RP-V-5C-M is a room-purpose, fully programmable, BACnet MS/TP based field controller dedicated for VAV cooling and Heating applications. The RP-V integrates a controller, a damper actuator, and an air flow sensor in a single compact package for ease of installation. The RP-V can either be used as a standalone field controller or as part of an EcoStruxure BMS with a SpaceLogic AS-P or AS-B server or an Enterprise Server as the parent server.

The RP-V has the following features:

Native BACnet MS/TP support

Integrated damper actuator with feedback signal

Factory-calibrated air flow sensor

Versatile onboard I/O point mix

Built-in isolated power supply

Advanced monitoring

Configurable RS-485 port

Sensor bus for SpaceLogic living space sensors

EasyLogic living space sensors

Modbus RTU subnetwork

Commission mobile application for commissioning of the controller before the BMS is in place

Full EcoStruxure Building Operation software support, providing efficient engineering tools

Upgrade with signed firmware

Native BACnet MS/TP support

The EasyLogic range of RP and MP controllers and RP-IO I/O modules natively communicate with automation servers and field devices using the BACnet MS/TP protocol.

The RS-485 port with 3-pole screw terminal block is used for connection to the BACnet MS/TP network.

The other RS-485 port (Com A), with RJ45 interface, can be configured to support either sensor bus or Modbus network. For more information, see section “Configurable RS-485 port”.

Versatile mix of I/O points

The RP-V-5C-M controller has an I/O point count and a versatile mix of I/O point types that match a wide variety of VAV applications. The universal inputs/outputs are highly flexible and can be configured as either inputs or outputs.

|

I/O Point Types |

RP-V-5C-M |

|

Universal I/O Type Ub |

2 |

|

Solid-state relay outputs (MOSFET) |

3 |

|

Configurations |

Universal I/O Type Ub |

Solid-state Relay Outputs (MOSFET) |

|

Digital inputs |

yes |

- |

|

Counter inputs |

yes |

- |

|

Supervised inputs |

yes |

- |

|

Voltage inputs (0 to 10 VDC) |

yes |

- |

|

Current inputs (0 to 20 mA) |

yes |

- |

|

Temperature inputs |

yes |

- |

|

Resistive inputs |

yes |

- |

|

Voltage outputs (0 to 10 VDC) |

yes |

- |

|

Digital outputs |

- |

yes |

|

Digital pulsed outputs |

- |

yes |

|

PWM outputs |

- |

yes |

|

Tristate outputs |

- |

yes |

|

Tristate pulsed outputs |

- |

yes |

The universal inputs/outputs are ideal for any mix of temperature, pressure, flow, status points, and similar point types in a building control system.

As counter inputs, the universal inputs/outputs are commonly used in energy metering applications. As supervised inputs, they are used for security applications where it is critical to know whether or not a wire has been cut or shorted. These events provide a separate indication of alarms and events in the system.

For all analog inputs, maximum and minimum levels can be defined to automatically detect over-range and under-range values.

The universal inputs/outputs are capable of supporting analog outputs of type voltage outputs. Therefore, the universal inputs/outputs support a wide range of devices, such as actuators.

Only devices with safe extra low voltage equipment (SELV/PELV) inputs/outputs should be connected to the universal inputs/outputs.

The solid-state relay (SSR) outputs can be used in many applications to switch 24 VAC or 24 VDC on or off for external loads such as actuators, relays, or indicators. SSRs are silent and are not adversely affected by relay contact wear.

For applications that require more I/O resources, the EasyLogic RP-IO modules provide a versatile mix of I/O points for any application. For more information, see the EasyLogic RP-IO Specification Sheet.

Integrated damper actuator with feedback signal

The integrated damper actuator allows for simplified installation of RP-V directly over the damper shaft. This means that separate installation, wiring, and positioning of the damper motor is not needed. RP-V uses the same actuator mechanics as MP-V and many Schneider Electric VAV controller models from the Andover Continuum, TAC Vista, TAC I/A Series, and TAC I/NET product lines. The feedback signal from the actuator makes it possible to determine the exact position of the damper. The actuator also features a push button for manual positioning of the damper during commissioning.

Factory-calibrated air flow sensor

The factory-calibrated air flow sensor uses a micro-flow channel integrated with the sensor chip that requires only a small air flow from the velocity probe. The sensor requires no maintenance and a minimum of field adjustments.

Built-in isolated power supply

The RP-V controller has a built-in power supply designed to accommodate 24 VAC input power. The AC power input (L and N) is galvanically isolated from the electronics. This minimizes the risk of damage due to earth currents and permits the input power to be wired without concern for AC polarity matching. With the isolated AC power input, you can use a central transformer for many RP-Vs, instead of one transformer for each RP-V, to reduce installation costs.

Advanced monitoring

The RP and MP controllers support local trends, schedules, and alarms, enabling local operation when the controller is offline or used in standalone applications.

The battery-free power backup of the memory helps prevent data loss and allows seamless and quick recovery after a power disruption.

In WorkStation, you update the firmware of multiple RP and MP controllers at the same time and with minimum down time. The EcoStruxure BMS server keeps track of the installed firmware to support backup, restore, and replacement of the controllers and sensors. The server can host controllers of different firmware versions.

Configurable RS-485 port

The RP-V-5C-M controller has one configurable RS-485 port (Com A), which can be configured to support two different types of networks:

Sensor bus

Modbus network

The controller can host one of the network types.

Sensor bus for SpaceLogic living space sensors

The RP and MP controllers provide an interface designed for the SpaceLogic Sensor family of living space sensors. The SpaceLogic Sensor devices offer an efficient way to sense the temperature, humidity, CO 2 , and occupancy in a room. The SpaceLogic Sensor devices are available with different combinations of sensor types and various covers and user interface options, such as touchscreen, setpoint and override buttons, and blank covers. For more information, see the SpaceLogic Sensors - SXWS Sensors for MP and RP IP Controllers - Specification Sheet.

The RP controller sensor bus provides both power and communications for up to four sensors that are daisy-chained using standard Cat 5 (or higher) cables. This maximum number of sensors that can be connected to a controller is regardless of the sensor model and the combination of cover and sensor base type:

Blank covers: Up to four sensors of any combination of sensor base types

3-button and touchscreen covers: Up to four sensors of any combination of sensor base types

SpaceLogic LCD temperature sensors: Up to four sensors are supported

The maximum total length of the sensor bus is 61 m (200 ft). For more information, see the SpaceLogic Sensors - SXWS Sensors for MP and RP IP Controllers - Specification Sheet.

EasyLogic living space sensors

The EasyLogic Sensor devices provide a cost-effective solution to measure, control, and communicate the temperature. The sensors are connected to analog inputs of the RP or MP controller. The EasyLogic Sensor devices are available in two models with different user interfaces, a blank cover or an LCD display with buttons for setpoint control. For more information, see the EasyLogic Sensors - Temperature Sensors – Analog - Specification Sheet.

Modbus RTU subnetwork

The RP controller Modbus network allows standard Modbus devices to be connected to the controller.

The Modbus RTU protocol is used for the communication. The RP controller acts as the Modbus client and the connected devices act as servers.

For connection to Modbus devices, it is recommended to use the non-isolated RS-485 adapter to provide screw termination. The adapter converts an RS-485 RJ45 interface to screw terminals. The adapter can be ordered from Schneider Electric. For more information, see the RS-485 Adapters Specification Sheet.

To connect the adapter, it is recommended that you use a Cat 5 (or higher) UTP cable with eight conductors and RJ45 connectors. The cable should be rated for the target environment and have a maximum length of 0.3 m (12 in.). The cable is not included and needs to be purchased separately.

The maximum number of Modbus devices that can be connected to an RP controller depends on the type of Modbus device and the number of Modbus registers.

The EasyLogic RP controller Modbus network supports up to 10 connected Modbus devices with the following restrictions:

Maximum of 250 Modbus registers per network

64-bit Modbus registers are supported, which can be used in energy metering.

Modbus device types are pre-configured Modbus applications for quick and easy Modbus device integration in EcoStruxure Building Operation solutions. For information on the Modbus devices supported using Modbus device types, see the document EcoStruxure Building - Modbus Device Integration - Supported Device Brochure.

Commission mobile application

The Commission mobile application is designed for local configuration, field deployment, commissioning of RP and MP controllers, and air flow balancing of VAV units. The mobile application reduces the commissioning time, allows flexibility in project execution, and minimizes dependencies on network infrastructure.

The mobile application is designed for use with Android, Apple (iOS), and Microsoft Windows 10 and Windows 11 devices. For more information, see the EcoStruxure Building Commission Specification Sheet.

Using the Commission mobile application, you can connect to an RP controller. To connect to the RP controller, you use the SpaceLogic Bluetooth Adapter connected to a SpaceLogic Sensor.

With the Commission mobile application, you can easily discover RP controllers on the BACnet network. You can change the configuration of each controller, including the BACnet network settings, location, and parent server. To save engineering time, you can save common device settings and then reuse them for controllers of the same model.

The Commission mobile application does not require an EcoStruxure BMS server or a network infrastructure to be in place. You can use the mobile application to load the controller application directly into the local controller and deploy the controller. The controller application can be created offline using Project Configuration Tool or WorkStation. You can also perform an I/O checkout to verify that the controller's I/O points are configured, wired, and operating correctly.

Using the Commission mobile application, you can perform air flow balancing of VAV units controlled by RP-Vs. An intuitive workflow automatically guides you through the process. After the flow balancing, you can generate a report in HTML format for one or more VAV units. The balancing parameters associated with each RP-V are stored in the parent server, which makes it easier to replace the controller if necessary.

Full EcoStruxure Building Operation software support

The power of the RP and MP controllers is fully realized when it is part of an EcoStruxure BMS, which provides the following benefits:

WorkStation/WebStation interface

Script and Function Block programming options

Device discovery

Engineering efficiency

WorkStation and WebStation provide a consistent user experience regardless of which EcoStruxure BMS server the user is logged on to. The user can log on to the parent EcoStruxure BMS server to engineer, commission, supervise, and monitor the RP or MP controller and its I/O as well as its attached SpaceLogic Sensor devices. For more information, see the WorkStation and WebStation specification sheets.

The fully programmable RP and MP controller models have both Script and Function Block programming options. Existing programs can easily be reused between the EcoStruxure BMS server and the controller.

The enhanced Device Discovery in WorkStation enables you to easily identify RP and MP controllers on a BACnet network and to associate the controllers with their parent server.

The engineering and maintenance of RP and MP controllers can be done very efficiently using the EcoStruxure Building Operation reusability features. With these features, you can create library items (Custom Types) for a complete controller application that contains programs and all necessary objects such as trends, alarms, and schedules. The controller application in the Custom Types library is reusable across all controllers of the same model. You can use the controller application as a base for creating new controllers intended for similar applications. You can then edit the controller application, and the changes are automatically replicated to all controllers, while each controller keeps its local values.

WorkStation supports both online and offline engineering of RP and MP controllers. You can make the configuration changes online or use database mode to make the changes offline. In database mode, the changes are saved to the EcoStruxure Building Operation database so that you can apply the changes to the controllers later.

Project Configuration Tool enables you to perform all the engineering off site, without the need for physical hardware, which minimizes the time you need to spend on site. You can run the EcoStruxure BMS servers virtually and engineer the RP and MP controllers before you deploy your server and controller applications to the servers and controllers on site. For more information, see the Project Configuration Tool specification sheet.

Upgrade with signed firmware

Using digitally signed firmware provides more secure upgrading of the device. During an upgrade, the device verifies that the firmware is authentic and uncompromised Schneider Electric firmware. If the device detects discrepancies in the authenticity or integrity of the firmware, it will reject the upgrade. Once the device is upgraded with signed firmware, all upgrades thereafter must be with a signed firmware version.

|

Product |

Part number |

|

RP-V-5C-M

|

SXWRPV5CM10001

|

|

Product |

Part number |

|

Adapter for damper shaft diameter 9.5 mm (0.375 inch)

|

AM-135

|

|

In-line air filter |

01-2100-272 |

|

Non-isolated RS-485 adapter

|

SXWNISORS48510001

|

|

SpaceLogic Bluetooth Adapter

|

SXWBTAECXX10001

|

For more information on part numbers for Network Connectivity Accessories, see the For more information, see Product Selection Guide - EcoStruxure Building ..

Specifications

| AC input | |||||||

Type

|

Isolated Class 2 input

|

||||||

Nominal voltage

|

24 VAC

|

||||||

Operating voltage range

|

+/-15 %

|

||||||

Frequency

|

50/60 Hz

|

||||||

Maximum power consumption

|

11 VA

|

||||||

|

|||||||

| a) The example of 4.6 VA for the Sensor Bus (Com A) is based on a 2.8 W load on Com A. This gives an approximate conversion factor of 1.644 VA per Watt, which can be applied to the Com A load, which should not exceed 3 W. | |||||||

Power input protection

|

MOV suppression and internal fuse

|

||||||

| Environment | |||||||

Ambient temperature, operating

|

0 to 50 °C (32 to 122 °F)

|

||||||

Ambient temperature, storage

|

-40 to +70 °C (-40 to +158 °F)

|

||||||

Maximum humidity

|

95 % RH non-condensing

|

||||||

| Material | |||||||

Plastic flame rating

|

UL94 V-0

|

||||||

Ingress protection rating

|

IP 20

|

||||||

| Mechanical | |||||||

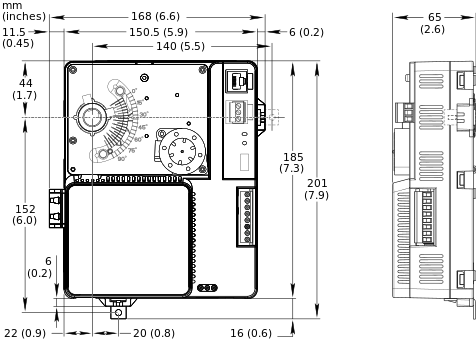

Dimensions

|

168 W x 201 H x 65 D mm (6.6 W x 7.9 H x 2.6 D in.)

|

||||||

|

|||||||

Weight

|

0.972 kg (2.143 lb)

|

||||||

Installation

|

Over the damper shaft

|

||||||

Terminal blocks

|

Power and I/O: Fixed

|

||||||

BACnet MS/TP communications: Removable

|

|||||||

| Compatibility | |||||||

EcoStruxure BMS server communication

|

|||||||

EcoStruxure Building Operation

|

version 4.0.3 and later

|

||||||

Modbus 64-bit register support

|

|||||||

EcoStruxure Building Operation

|

version 5.0.1 and later

|

||||||

| Agency compliances | |||||||

Emission

|

RCM; BS/EN 61000-6-3; BS/EN IEC 63044-5-2; FCC Part 15, Sub-part B, Class B

|

||||||

Immunity

|

BS/EN 61000-6-2; BS/EN IEC 63044-5-3

|

||||||

Safety standards

|

BS/EN 60730-1; BS/EN 60730-2-11; BS/EN IEC 63044-3; UL 916 C-UL US Listed

a

|

||||||

| a) The RP-V-5C-M model is marked “Energy Management Equipment”. | |||||||

Fire performance in air-handling spaces

a

|

UL 2043

|

||||||

| a) The RP-V-5C-M model is approved for plenum applications. | |||||||

| Communication ports | |||||||

RS-485 port Com A

|

24 VDC, 3 W, RS-485 (RJ45)

|

||||||

Transient voltage suppressors on communication and power signals

|

|||||||

RS-485 port Com B

|

RS-485 (3-pole screw terminal block)

|

||||||

Transient voltage suppressors on communication signals

|

|||||||

| RS-485 transceiver characteristics | |||||||

Transceiver type

|

Failsafe

|

||||||

Non-isolated

|

|||||||

External biasing

|

None required

|

||||||

Total Unit Load (UL) per device

|

Maximum 0.5 UL

|

||||||

| Communications | |||||||

BACnet

|

BACnet MS/TP, maximum bus length: 1200 m (4000 ft), maximum baud rate: 76800

|

||||||

BTL B-AAC (BACnet Advanced Application Controller)

a

|

|||||||

| a) See the BTL Product Catalog for up-to-date details on BTL listed firmware revisions on BACnet International's home page. | |||||||

| CPU | |||||||

Frequency

|

500 MHz

|

||||||

Type

|

ARM Cortex-A7 single-core

|

||||||

Internal SRAM

|

6 MB

|

||||||

NOR flash memory

|

32 MB

|

||||||

Memory backup

|

128 kB

a

, FRAM, non-volatile

|

||||||

| a) RP-V-5C-M with hardware version earlier than 05 has a FRAM memory with a size of 8 kB. For these hardware versions, the use of Script programs is recommended to save FRAM memory space. | |||||||

| Damper actuator | |||||||

Torque rating

|

10 Nm (88.5 lbf.in)

|

||||||

Stroke

|

0° to 90°, fully adjustable

|

||||||

Timing

|

Approximately 2 seconds/degree at 60 Hz and 2.4 seconds/degree at 50 Hz

|

||||||

Position indication

|

Visual indication

|

||||||

Damper position feedback

|

Yes

|

||||||

Manual override

|

Push-button clutch release

|

||||||

Damper shaft diameter

|

12.7 mm (0.5 inch) or 9.5 mm (0.375 inch)

|

||||||

Adapter kit AM-135 is required for 9.5 mm (0.375 inch) diameter shafts.

|

|||||||

Damper shaft minimum length (from VAV box)

|

22.2 mm (0.875 inch)

|

||||||

| Air flow sensor | |||||||

Range

|

0 to 249 Pa (0 to 1 inH

2

O)

|

||||||

Resolution

|

0.0167 Pa (0.000067 inH

2

O)

|

||||||

Accuracy

|

±5% of reading (typical) at 25°C (77°F)

|

||||||

| Universal inputs/outputs | |||||||

Channels

|

2 Ub, Ub1 to Ub2

|

||||||

Absolute maximum ratings

|

-0.5 to +24 VDC

|

||||||

A/D converter resolution

|

16 bits

|

||||||

Universal input/output protection

|

Transient voltage suppressor on each universal input/output

|

||||||

| Digital inputs | |||||||

Range

|

Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

|

||||||

Minimum pulse width

|

150 ms

|

||||||

| Counter inputs | |||||||

Range

|

Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

|

||||||

Minimum pulse width

|

20 ms

|

||||||

Maximum frequency

|

25 Hz

|

||||||

| Supervised inputs | |||||||

5 V circuit, 1 or 2 resistors

|

|||||||

Monitored switch combinations

|

Series only, parallel only, and series and parallel

|

||||||

Resistor range

|

1 to 10 kohm

|

||||||

| For a 2-resistor configuration, each resistor must have the same value +/- 5 % | |||||||

| Voltage inputs | |||||||

Range

|

0 to 10 VDC

|

||||||

Accuracy

|

+/-(7 mV + 0.2 % of reading)

|

||||||

Resolution

|

1.0 mV

|

||||||

Impedance

|

1 Mohm

|

||||||

| Current inputs | |||||||

Range

|

0 to 20 mA

|

||||||

Accuracy

|

+/-(0.01 mA + 0.4 % of reading)

|

||||||

Resolution

|

1 μA

|

||||||

Impedance

|

47 ohm

|

||||||

| Resistive inputs | |||||||

10 ohm to 10 kohm accuracy

|

+/-(7 + 4 x 10

-3

x R) ohm

|

||||||

| R = Resistance in ohm | |||||||

10 kohm to 60 kohm accuracy

|

+/-(4 x 10

-3

x R + 7 x 10

-8

x R

2

) ohm

|

||||||

| R = Resistance in ohm | |||||||

| Temperature inputs (thermistors) | |||||||

Range

|

-50 to +150 °C (-58 to +302 °F)

|

||||||

| Supported thermistors | |||||||

Honeywell

|

20 kohm

|

||||||

Type I (Continuum)

|

10 kohm

|

||||||

Type II (I/NET)

|

10 kohm

|

||||||

Type III (Satchwell)

|

10 kohm

|

||||||

Type IV (FD)

|

10 kohm

|

||||||

Type V (FD w/ 11k shunt)

|

Linearized 10 kohm

|

||||||

Satchwell D?T

|

Linearized 10 kohm

|

||||||

Johnson Controls

|

2.2 kohm

|

||||||

Xenta

|

1.8 kohm

|

||||||

Balco

|

1 kohm

|

||||||

| Measurement accuracy | |||||||

20 kohm

|

-50 to -30 °C: +/-1.5 °C (-58 to -22 °F: +/-2.7 °F)

|

||||||

-30 to 0 °C: +/-0.5 °C (-22 to +32 °F: +/-0.9 °F)

|

|||||||

0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

|

|||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||

10 kohm, 2.2 kohm, and 1.8 kohm

|

-50 to -30 °C: +/-0.75 °C (-58 to -22 °F: +/-1.35 °F)

|

||||||

-30 to +100 °C: +/-0.2 °C (-22 to +212 °F: +/-0.4 °F)

|

|||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||

Linearized 10 kohm

|

-50 to -30 °C: +/-2.0 °C (-58 to -22 °F: +/-3.6 °F)

|

||||||

-30 to 0 °C: +/-0.75 °C (-22 to +32 °F: +/-1.35 °F)

|

|||||||

0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

|

|||||||

100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

|

|||||||

1 kohm

|

-50 to +150 °C: +/-1.0 °C (-58 to +302° F: +/-1.8 °F)

|

||||||

| Voltage outputs | |||||||

Range

|

0 to 10 VDC

|

||||||

Accuracy

|

+/-60 mV

|

||||||

Resolution

|

10 mV

|

||||||

Minimum load resistance

|

2.4 kohm

|

||||||

Source current

|

+4.2 mA

|

||||||

Sink current

|

-1 mA (0 to 0.4 VDC)

|

||||||

-4.2 mA (0.4 to 10 VDC)

|

|||||||

| Solid-state relay outputs, DO | |||||||

Channels

|

3, DO1 to DO3

|

||||||

Output rating

|

Maximum 1.5 A load per output

|

||||||

Maximum 3 A total load for the 3 outputs

|

|||||||

AC voltage range

|

Maximum 30 VAC

|

||||||

DC voltage range

|

Maximum 30 VDC

|

||||||

Commons

|

COM for DO1, DO2, and DO3

|

||||||

| When the SSR outputs are used to switch AC, the common terminals can be connected to 0 to 30 VAC. When the SSR outputs are used to switch DC, the common terminals can be connected to -30 VDC to +30 VDC. | |||||||

Common voltage range (AC)

|

0 to 30 VAC

|

||||||

Common voltage range (DC)

|

-30 to +30 VDC

|

||||||

Minimum pulse width

|

100 ms

|

||||||

Solid-state relay output protection

|

Transient voltage suppressor across each solid-state relay (SSR) output

|

||||||

Terminals

For more information on wiring, see Hardware Reference Guide.

Enterprise Server

Enterprise Server

SpaceLogic AS-P

SpaceLogic AS-P

SpaceLogic AS-B

SpaceLogic AS-B

WorkStation

WorkStation

WebStation

WebStation

Commission

Commission

Project Configuration Tool – Version 2

Project Configuration Tool – Version 2

EasyLogic RP-IO

EasyLogic RP-IO