Concept

Non-isolated RS-485 Adapter Connection and Wiring

The Non-isolated RS-485 Adapter is equipped with an RJ45 port for connection to an RP or MP controller RS-485 Com port and a 4-position removable screw terminal block for connection to a BACnet MS/TP (RS-485) network or Modbus RTU (RS-485) subnetwork.

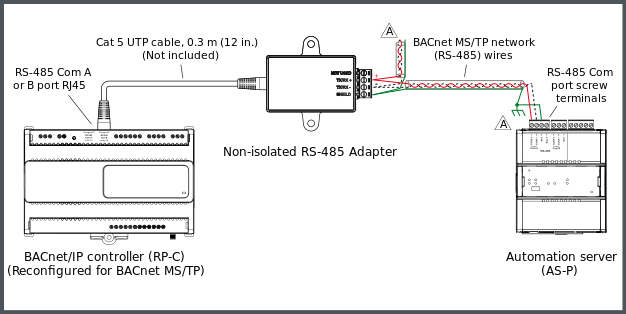

Connection to a BACnet MS/TP network

The following figure shows an example of how a Non-isolated RS-485 Adapter is connected to one of the RS-485 Com ports (RJ45) of an RP-C controller via a Cat 5 (or higher) UTP cable of maximum length 0.3 m (12 in.) and how the BACnet MS/TP network (RS-485) wires from the adapter are connected to the RS-485 Com port screw terminals of an AS-P server.

Follow the recommendations and guidelines for the RS-485 interface configuration in regard to data rate, biasing, termination, cable selection, cable length, and cable routing. For more information, see RS-485 Communications .

A separate connection cable is required to connect the RJ45 port on the RS-485 adapter to the RS-485 Com port (RJ45) on the BACnet/IP controller. The cable is not included and needs to be purchased separately.

Use a Cat 5 (or higher) unshielded, straight-through wired cable with eight conductors (four twisted pairs) and RJ45 connectors. Use a cable with the wire size (cross-sectional area) 22 to 26 AWG (0.34 to 0.14 mm²), a maximum length of 0.3 m (12 inches), and a rating that meets the requirements of the target environment. For example, when devices are installed in a space that handles conditioned air or return air, the cables typically need to be plenum-rated.

For more information, see Connecting a Non-isolated RS-485 Adapter .

For more information, see RJ45 Pinout for the RS-485 Port of the MP-V Controller .

For more information, see RJ45 Pinout for the RS-485 Port(s) of the RP-C Controllers .

For more information, see RJ45 Pinout for the RS-485 Port(s) of the RP-V Controllers .

The four screw terminals are wired and connected to a BACnet MS/TP (RS-485) network as described in the following table.

Recommended screw tightening torque: 0.5 Nm (4.5 lbf.in)

|

Terminal |

Usage |

|

NOT USED |

Not connected. |

|

TX/RX+ |

Data line (+) for connection to the TX/RX+ signal in the BACnet MS/TP twisted pair connecting all devices on the bus. |

|

TX/RX– |

Data line (–) for connection to the TX/RX– signal in the BACnet MS/TP twisted pair connecting all devices on the bus. |

|

SHIELD |

Convenience terminal to interconnect two shield drain wires (incoming and outgoing). There is no electrical connection in the device. The shield should be connected to ground at only one location and that is recommended to be at the automation server. The shield should not be connected directly to the RET terminal on the automation server. The transient energy on the drain wire should be conducted to ground and not through the automation server. |

For more information, see Wiring the Screw Terminals on a Non-isolated RS-485 Adapter .

For more information, see RS-485 Communications .

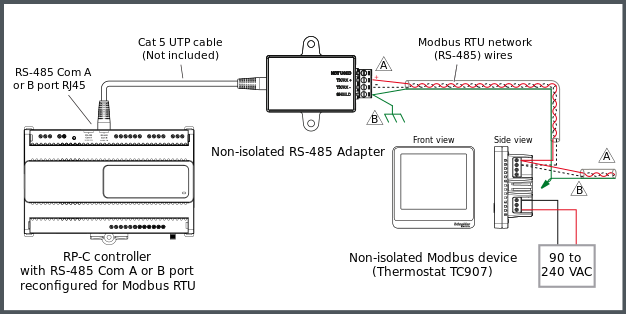

Connection to a Modbus RTU subnetwork

The following figure shows an example of how a Non-isolated RS-485 Adapter is connected to one of the RS-485 Com ports (RJ45) of an RP-C controller via a Cat 5 (or higher) UTP cable and how the Modbus RTU network twisted pair wires from the adapter are connected to the screw terminals of a Modbus device. In this example, the Modbus device is a thermostat from the SpaceLogic Thermostat TC907 Series. Additional Modbus devices may be daisy-chained from the thermostat.

The twisted pair cable used for TX/RX+ and TX/RX- data wires extends in one direction from the adapter to each device in a daisy chain bus configuration without cable stubs.

Follow the recommendations and guidelines for the RS-485 interface configuration in regard to data rate, biasing, termination, cable selection, cable length, and cable routing. For more information, see RS-485 Communications .

A separate connection cable is required to connect the RJ45 port on the RS-485 adapter to the RS-485 Com port (RJ45) on the RP or MP controller. The cable is not included and needs to be purchased separately.

Use a Cat 5 (or higher) unshielded, straight-through wired cable with eight conductors (four twisted pairs) and RJ45 connectors. Use a cable with the wire size (cross-sectional area) 22 to 26 AWG (0.34 to 0.14 mm²), and a rating that meets the requirements of the target environment. For example, when devices are installed in a space that handles conditioned air or return air, the cables typically need to be plenum-rated.

For more information, see Connecting a Non-isolated RS-485 Adapter .

For more information, see Communication Port Wiring .

For more information, see RJ45 Pinout for the RS-485 Port of the MP-V Controller .

For more information, see RJ45 Pinout for the RS-485 Port(s) of the RP-C Controllers .

For more information, see RJ45 Pinout for the RS-485 Port(s) of the RP-V Controllers .

The four screw terminals are wired and connected to a Modbus RTU (RS-485) subnetwork as described in the following table.

Recommended screw tightening torque: 0.5 Nm (4.5 lbf.in)

|

Terminal |

Usage |

|

NOT USED |

Not connected. |

|

TX/RX+ |

Data line (+) for connection to the TX/RX+ signal in the Modbus RTU twisted pair connecting all devices on the bus. |

|

TX/RX– |

Data line (–) for connection to the TX/RX– signal in the Modbus RTU twisted pair connecting all devices on the bus. |

|

SHIELD |

Convenience terminal to interconnect two shield drain wires (incoming and outgoing). There is no electrical connection in the device. The shield should be connected to ground at only one location and that is recommended to be at the hosting RP or MP controller. The shield should be connected through to the next segment at each device without additional connections to ground. The shield should not be connected directly to the SHIELD terminal on the adapter. The transient energy on the drain wire should be conducted to ground and not through the adapter and on to the controller. |

For more information, see Wiring the Screw Terminals on a Non-isolated RS-485 Adapter .

For more information, see RS-485 Communications .

RS-485 Adapters

RS-485 Adapters

Non-isolated RS-485 Adapter

Non-isolated RS-485 Adapter

Connecting a Non-isolated RS-485 Adapter

Connecting a Non-isolated RS-485 Adapter

RJ45 Pinout for the RS-485 Port(s) of the RP-C Controllers

RJ45 Pinout for the RS-485 Port(s) of the RP-C Controllers

RJ45 Pinout for the RS-485 Port of the MP-V Controller

RJ45 Pinout for the RS-485 Port of the MP-V Controller

Wiring the Screw Terminals on a Non-isolated RS-485 Adapter

Wiring the Screw Terminals on a Non-isolated RS-485 Adapter

RS-485 Communications

RS-485 Communications

Communication Ports on RP-C Models with “-F” in the Product Name

Communication Ports on RP-C Models with “-F” in the Product Name

RP-C BACnet MS/TP Support

RP-C BACnet MS/TP Support

Wiring

Wiring