Concept

Smoke Control Enclosures and Requirements

You must install most of the controls products listed here in an enclosure that meets the following minimum criteria. After the criteria, several specific enclosure models are listed as examples of enclosures that meet the minimum criteria you can use for the smoke control system.

Any enclosures you use to house controllers and products participating in the smoke control system must be UL Listed under one of the following UL Standards:

UL 50 Enclosures for Electrical Equipment

UL 508/508A Industrial Control Panels

UL 864 Control Units and Accessories for Fire Alarm Systems

Compliance with one of those standards will regulate the dimensions of the enclosures sides (height, width, depth), the gauge of metal used to produce the enclosure and the strengthening/forming of the metal necessary for the gauge metal used.

The enclosures you use for the PS-24V, Smoke Control Servers and the I/O modules must also provide a minimum metal surface area based on the power (watts) being dissipated inside the enclosure.

The selected metal enclosure must provide a minimum volume of 125 cubic inches for each watt of power that is dissipated in the enclosure. The value referenced here now extracts the 10 watts for the PS24V supply that was fixed in the previous document calculation. The calculated PS24V watts is now added to the accumulated IO bus device power in the enclosure as described in the following examples. This scheme accommodates the additional power encountered when more than one PS24V is mounted in the enclosure and also those situations where no PS24V is required in the enclosure.

For example, an enclosure that measures 24 inches (610 mm) high x 24 inches (610 mm) wide x 10 inches (254 mm) deep provides a volume of 5760 cubic inches. Dividing 5760 by 125 produces a max power value of 46 watts. For the 24x24x10 sized enclosure, the sum of the name plate power ratings for the Smoke Control Server and I/O modules and the calculated PS24V power and any accessory devices must not exceed the 46 watts value.

The PS24V power reaches the 10W maximum when its output is the full 30W to the server and I/O modules on the bus. To calculate the PS24V power disipation, you multiply the percentage of full output power by 10 and enter the resulting value in the accumulated power table as follows.

PS24V Power Disipation = Output Watts / 30 * 10

This is demonstrated in the following examples.

In your calculations, be sure to also include any accessory items such as an EIS series Ethernet Switch (6W for Copper version and 10W for Fiber version) and the 24 VAC power transformer (if mounted in the same enclosure).

The approved 24 VAC transformers listed in the guide have output ratings ranging from 40 VA to 240 VA. The efficiency of the transformer determines the amount of that maximum load VA that will be dissipated in the enclosure as heat. To determine the transformer watts used for accumulating total watts consumed in the enclosure, use the following table.

|

Transformer Model # |

Output Rating VA |

Mfg. Model |

Watts in Enclosure |

|

EMSC-541 |

50 |

88-50 |

17.6W |

|

EMSC-542 |

100 |

88-100 |

35.3W |

|

EMSC-543 |

240 |

TR240VA001 X240DAA |

53.4W |

|

EMSC-583 |

75 |

LE11800 120-024-075-2TF-CB |

26.4W |

|

EMSC-616 |

75 |

TR75VA001 X075CAA |

16.6W |

|

EMSC-618 |

96 |

TR100VA001 X100CAA |

21.4W |

|

LE10500 |

40 |

LE10500 024-024-040-1TF |

14.2W |

|

01-2100-323 |

40 |

YD60B-017 E66-40-BW-9920 |

14.2W |

Select the Transformer Model and using the Watts In Enclosure value, add that value to the sum of the Smoke Control and I/O module power ratings.

The transformer Watts In Enclosure values listed here represent the inefficiency of the transformers delivered as heat in the enclosure and include an added margin required for the agency approval at this time.

An Automation Server AS-P-SMK with the following I/O collection is packaged for installation in the smoke control system.

|

Model |

Watts |

|

AS-P UI-8-AO-V-4-H DO-FA-12-H UI-16 |

10.0 1.0 1.8 1.8 |

|

Bus Load Subtotal PS24V Power (14.6/30*10) |

14.6 4.86 |

|

Subtotal EMCS-616 Transformer |

19.46 16.6 |

|

Total Watts |

36.06 Watts |

In this example, the total watts of 36.06 Watts multiplied by 125 cu.in. = 4508 cubic inches. This is the minimum enclosure size needed for thermal dissipation for the application using the I/O, AS-P-SMK server and transformer included here.

If you are using the earlier AS-SMK (Automation Server), then you enter 7W in place of the 10W in the table. This provides a bus load subtotal of 11.6W producing a PS24V power of 3.86W with a Total Watts of 32.06W. This power requires a minimum cubic inch size of 4008.

An enclosure such as a 24 inch (610 mm) x 24 inch (610 mm) x 8 inch (203.2 mm) enclosure provides 4608 cubic inches and supports the configurations listed previously.

An Automation Server (AS-SMK), or AS-P (AS-P-SMK) with the following I/O collection is packaged for installation in the smoke control system.

|

Model |

Watts |

|

AS-P UI-8-AO-V-4-H DO-FA-12-H UI-16 AO-8-H AO-V-8-H UI-16 DO-FC-8 UI-8/DO-FC-4-H DI-16 |

10.0 1.0 1.8 1.8 4.9 0.7 1.8 2.2 1.9 1.6 |

|

Bus Load Subtotal PS24V Power (27.7/30*10) |

27.7 9.23 |

|

Subtotal EMCS-616 Transformer |

36.93 16.6 |

|

Total Watts |

53.53 Watts |

In this example, the total watts of 53.53 multiplied by 125 cu.in. = 6691 cubic inches. This is the minimum enclosure size needed for thermal dissipation for the application using the listed I/O and the AS-P-SMK server included here.

If you use the earlier AS-SMK (Automation Server), then you enter 7W in place of the 10W in the table. This provides a bus load subtotal of 24.7W producing a PS24V power of 8.23W and a Total Watts of 49.53W. This power requires a minimum cubic inch size of 6191.

An enclosure such as the UNM-SCH243610RC enclosure provides 8640 cubic inches so you can use this size or larger for the application.

If the EIS8-100T Ethernet switch is included in the enclosure with the Smoke Control Servers, it adds 6 watts (nameplate rating on the EIS) to the total equalling 59.53 watts for the AS-P + I/O arrangement listed above. This requires a minimum of 7441 cubic inches, so the added equipment is still accomodated within the 8640 cubic inch enclosure.

A collection of the MP-C series controller models is packaged for installation in the smoke control system. The approved transformer is mounted in a separate enclosure.

|

Model |

Watts |

|

MP-C-15A-SMK MP-C-18B-SMK IP-IO-UIO5DOFA4-SMK |

12.0 12.0 9.0 |

|

Total Watts |

33.0 Watts |

The total watts of 33 multiplied by 125 cu.in. = 4125 cubic inches, so a minimum enclosure size like the SEBOX242408 is needed here. It provides 4400 cubic inches, so it is an applicable candidate here. The watts rating used for the various MP-X models for the enclosure size are as follows.

|

Model |

Watts |

|

MP-C-15A-SMK MP-C-18A-SMK MP-C-18B-SMK MP-C-24A-SMK MP-C-36A-SMK IP-IO-D10-SMK IP-IO-UIO10-SMK IP-IO-UIO5DOFA4-SMK |

12 12 12 15 18 9 9 9 |

The MP-V-7A-SMK and the MP-V-9A-SMK VAV controllers are intended for mounting in the approved MNA-FLO-1 housing. This housing provides complete ventilation to the surrounding area and the minimum size does not apply to the MNA-FLO-1.

When installing the transformer in the enclosure with the electronics, you must position the transformer so a 3-inch vertical space/gap exists between it and the electronics modules. The position must provide a 1-inch horizontal space/gap.

The transformer presents the largest watt element in the power accumulation described here. You may choose to place the transformer(s) in a separate enclosure next to the enclosure holding the servers, I/O modules and controllers and allow a smaller enclosure for the controllers. The minimum size restrictions discussed here are associated with maintaining enclosure internal temperature for the benefit of the Automation Server, AS-P and associated electronics modules. When you use a separate enclosure to house only the transformer(s), it does not need to provide the minimum capacities described here.

Enclosures

Schneider Electric provides several general purpose enclosures recommended for use with the EcoStruxure BMS smoke control system including the following:

SEBOX Series

MNA-FLO-1

MNB-300-ENC

UL-ENCL

SEBOX Series Enclosures

SEBOX includes a series of NEMA 4 rated enclosures with the following features:

UL Listed under UL 508A on file E103582

Large embedded cable-entry plate with neoprene seal

Standard 3-mm double-bar lock with screw driver lock feature

Foamed-in polyurethane gasket doors that guarantee water and dust tightness

Removable and reversible door with hinges allowing door to open 120°

Available with optional field-installed perforated subpanel

Epoxy-polyester resin finish, color RAL 7035 grey

A variety of SEBOX enclosure sizes are available as shown in the table that follows.

|

Model Number |

Width |

Height |

Depth |

Volume Cubic Inches |

|

SEBOX121806 |

11.8 in (300 mm) |

17.7 in (450 mm) |

5.9 in (150 mm) |

1232 (20, 188 cm) |

|

SEBOX161608 |

15.6 in (400 mm) |

15.6 in (400 mm) |

7.9 in (200 mm) |

1922 (31505 cm) |

|

SEBOX202010 |

19.7 in (500 mm) |

19.7 in (500 mm) |

9.8 in (250 mm) |

3803 (62324 cm) |

|

SEBOX242408 |

23.6 in (600 mm) |

23.6 in (600 mm) |

7.9 in (200 mm) |

4400 (72103 cm) |

|

SEBOX392410 |

39.4 in (1000 mm) |

23.6 in (600 mm) |

9.8 in (250 mm) |

9112 (149326 cm) |

|

SEBOX393210 |

39.4 in (1000 mm) |

31.5 in (800 mm) |

9.8 in (250 mm) |

12162 (199312 cm) |

|

SEBOX483212 |

47.2 in (1200 mm) |

31.5 in (800 mm) |

11.8 in (300 mm) |

17544 (287498 cm) |

|

The P suffix is added at the end of the model numbers when the internal perforated panel is required. |

Unity Series Enclosures

Prior to the introduction of the SEBOX series wall-mounted enclosures, Schneider Electric provided a collection of wall-mounted enclosures referred to as the Unity Series enclosures. These are no longer supplied by Schneider Electric. However, you can still acquire them directly from Unity Manufacturing (see the following details). On existing projects, it may be appropriate and more convenient to expand or revise a project with the same style and size enclosures as previously installed.

|

Model Number |

Material |

Width |

Height |

Depth |

Volume Cubic Inches |

|

UNM-SCH13186RC |

16gaCRS |

13 in (330 mm) |

18 in (457 mm) |

6 in (152 mm) |

1410 (23,105 cm) |

|

UNM-SCH181810RC |

16gaCRS |

18 in (457 mm) |

18 in (457 mm) |

10 in (254 mm) |

3240 (53,094 cm) |

|

UNM-SCH242410RC |

16gaCRS |

24 in (610 mm) |

24 in (610 mm) |

10 in (254 mm) |

5760 (94,389 cm) |

|

UNM-SCH243610RC |

16gaCRS |

24 in (610 mm) |

36 in (914 mm) |

10 in (254 mm) |

8640 (141,584 cm) |

|

UNM-SCH303610RC |

14gaCRS |

30 in (762 mm) |

36 in (914 mm) |

10 in (254 mm) |

10800 (176,980 cm) |

|

UNM-SCH304810RC |

14gaCRS |

30 in (762 mm) |

48 in (1219 mm) |

10 in (254 mm) |

14400 (235,973 cm) |

The Unity Manufacturing enclosures are UL50 listed enclosures not sold through Schneider Electric. You must obtain them directly from Unity at the following address:

Unity Manufacturing

210 E. Buckingham Rd.

Garland Texas 75040

972-272-9502

The following figure shows the construction of the UNM-SCH13186RC enclosure.

The next figure shows the larger and stronger UNM-SCH 303610RC enclosure.

The construction here is typical of the other UNM models UNM-SCH181810RC through UNM-SCH304810RC.

The UNM series enclosures do not have predefined knockout locations. You may punch conduit connection holes on any of the four sides (top, bottom, left, or right).

Ensure that the power limited wiring in the enclosure is separated from the non-power limited wiring, such as the line voltage to the transformers and possible Digital Output relay output control wiring. Refer to the UL 864 Smoke Control System Enclosure Guide for additional information on the enclosures, their general requirements, and available options.

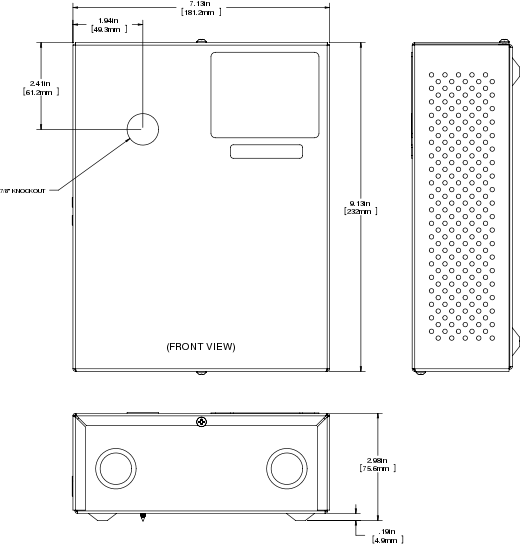

The MNA-FLO-1 is a small enclosure designed for mounting over the damper shaft and fastening to the VAV box panel. The MNA-FLO-1 accomodates the internal mounting of VAV controllers, such as the MP-V-7A-SMK, MP-V-9A-SMK, b3865-V-S, b3866-V-S, b3885-V-S, MNB-V1-2 and MNB-V2-2. The following figure shows the MNA-FLO-1 enclosure.

The MNA-FLO-1 provides knockouts in the positions shown for .50 inch (13 mm) or .75 inch (19 mm) conduit connections.

The MNB-300-ENC is a small enclosure designed specifically to house the MNB-300 controller. You can mount this enclosure on a wall or panel. Four integrated mounting studs are provided in the base for attaching the MNB-300.

Conduit connections are supported with two knockouts along the top and bottom of the unit. Each knockout provides a double size supporting a 0.875 inch (22 mm) hole for .50 inch (13 mm) conduit, or a 1.125 inch (28 mm) hole for .75 inch (19 mm) conduit.

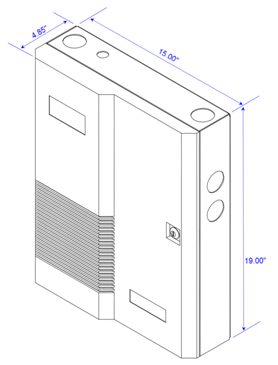

The UL-ENCL is a small, general purpose enclosure typically used with field controllers. This enclosure is 19 inches (483 mm) high, 15 inches (381 mm) wide, and approximately 4 inches (102 mm) deep, including a 3 inch (76 mm) base with a two tiered door. Vent louvres are provided on the left and right sides of the enclosure.

You can wall mount this enclosure using the two key slot holes (.28 inch (7 mm) x .50 inch (13 mm)) along the top of the enclosure and two .28 inch (7 mm) along the bottom of the enclosure.

The UL-ENCL enclosure does not feature a DIN rail. Instead, you mount controllers and expansion modules using screws fastened through the pre-drilled backplate. A key lock and a tamper switch are also provided for added security. The enclosure provides space to accommodate controller and power transformer mounting.

For conduit connections, 1.65 inch (42 mm) knockouts are available on the right (2), left (1), top (2), bottom (2) and rear (2).

Ensure that the power limited wiring in the enclosure is separated from the non-power limited wiring, such as the line voltage to the transformer and possible relay output control wiring. The minimum separation is .25 inch (6 mm).

The I2-ENCL-S enclosure is the same design and is used for the same applications as the model UL-ENCL enclosure described previously. The model UL-ENCL replaces the I2-ENCL-S enclosure. However, you may encounter existing I2-ENCL-S enclosures when upgrading an existing system to an EcoStruxure BMS smoke control system. The continued use of the I2-ENCL-S enclosure is approved in the EcoStruxure BMS.

The 3P-UL-ENCL enclosure is a legacy system enclosure typically used with Continuum DIN rail mounted controller products. The enclosure measures 36 inches (913 mm) x 24 inches (610 mm) x 6.5 inches (165 mm) (Height x Width x Depth) and provides 3 DIN rails that you can use for mounting the power supply, controller and I/O modules. Generally, the Unity series enclosures are used for new system installations, but the 3P-UL-ENCL is also approved for use in the EcoStruxure BMS smoke control system.

The VAV-ENCL-S is a small enclosure specifically designed for VAV controllers such the b3865-S and b3866-S. This enclosure is not typically sold with new systems. However, you may frequently encounter it when upgrading previous systems to the EcoStruxure BMS smoke control system. You can also use this enclosure when changing to any of the other VAV controllers listed in this guide.

This enclosure is 14.25 inches (362 mm) high, 12.3 inches (312 mm) wide, and approximately 4 inches (102 mm) deep. A .88 inch (22 mm) hole is provided in the rear for insertion of the VAV damper shaft and mating with the VAV actuator collar. For conduit connections, three knockouts are provided on the bottom and one on the right of the unit.

Ensure that the power limited wiring in the enclosure is separated from the non-power limited wiring, such as the line voltage to the transformer and the relay output control wiring. The minimum separation is .25 inch (6 mm).

The Unity series enclosures have been in wide use for a number of years with the Continuum series controllers. The SEBOX and Unity enclosure models referenced here are approved for use with smoke control systems for housing the legacy controller models described in this guide. These enclosures provide additional space for the controllers, accessories, and the segregation and routing of controller wiring.

When used with the b3, i2, b-Link, Infilink and other referenced accessory items, select the enclosure size that achieves a metal enclosed volume of 71 cubic inches (or larger) per watt using the accumulated ratings for the controller devices. You can include one of the transformers listed in this guide (40VA up to 100VA) in the enclosure. For more information, see Transformers .

You must position the legacy controller assemblies and accessory electronics devices in the enclosure to provide a minimum vertical space of 1 inch (25 mm) above the transformer and a minimum horizontal space of .50 inch (13 mm) between the transformer and the electronics.

As an example, consider the following legacy application.

The most commonly used model UNM-SCH242410RC enclosure provides a 24 inch (610 mm) x 24 inch (610 mm) x 10 inch (254 mm) size that you can use to house a b3/i2920 controller along with the two supported xP expansion modules. The controller is 45VA and the expansion is 6VA (maximum for the two xP modules) giving a total of 51VA. This delivers 123 cubic inches per watt which exceeds the 71 cubic inch minimum.

EcoStruxure BMS Hardware Overview

EcoStruxure BMS Hardware Overview

MS/TP BACnet Field Controllers

MS/TP BACnet Field Controllers

Infinet i2 Series Field Controllers

Infinet i2 Series Field Controllers

MS/TP Network Accessories

MS/TP Network Accessories

Infinet i2 Network Accessories

Infinet i2 Network Accessories

SEBOX121806 Enclosure

SEBOX121806 Enclosure

SEBOX161608 Enclosure

SEBOX161608 Enclosure

SEBOX202010 Enclosure

SEBOX202010 Enclosure

SEBOX242408 Enclosure

SEBOX242408 Enclosure

SEBOX392410 Enclosure

SEBOX392410 Enclosure

SEBOX393210 Enclosure

SEBOX393210 Enclosure

MNA-FLO-1 Enclosure

MNA-FLO-1 Enclosure

FSCS and FAP Introduction

FSCS and FAP Introduction

EcoStruxure BMS Overview

EcoStruxure BMS Overview

Transformers

Transformers